DEHA:ERP

Comprehensive Management Solution for Manufacturing

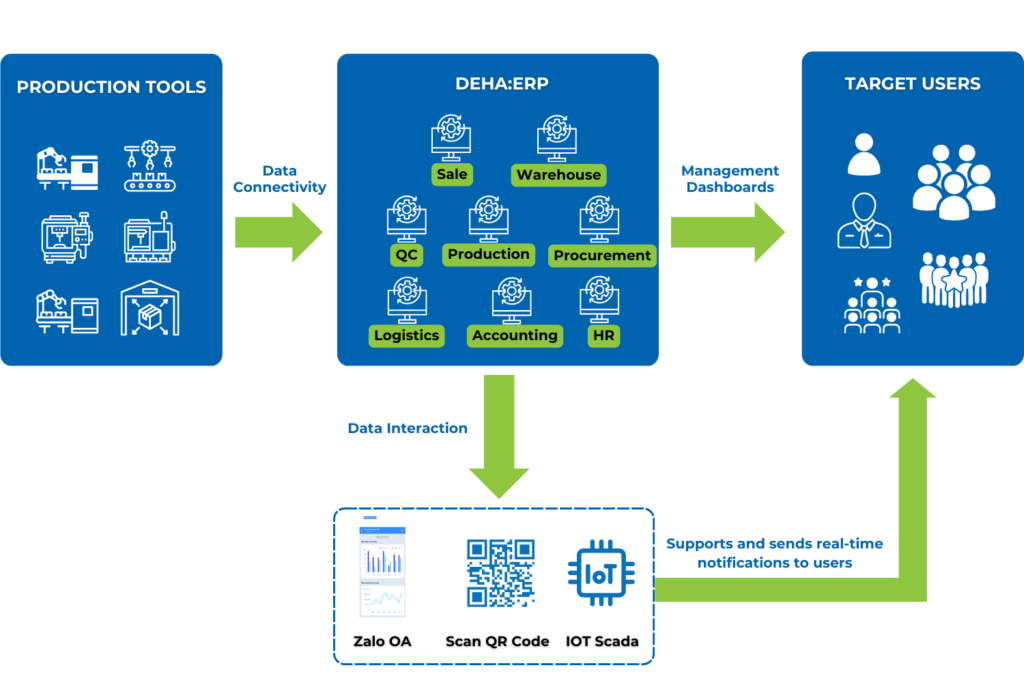

- An ERP solution designed to meet the specific requirements of each type of manufacturing business.

- Easily integrates with SCADA and IIoT systems.

Overview of DEHA:ERP Solution

01

DEHA:ERP is a management system designed and customized to address the strategic needs and practical challenges of manufacturing enterprises. This ERP solution supports manufacturers of all sizes in managing and automating their core operations more efficiently.

02

By combining advanced technology with modules that seamlessly connect operations across departments, DEHA:ERP helps boost productivity and enables comprehensive data management on a single platform,

paving the way for smarter, data-driven decision-making.

03

In addition to enhancing business performance, DEHA:ERP streamlines operational processes and strengthens competitiveness by improving localization capabilities and addressing supply chain disruptions.

Benefits of DEHA:ERP Solution

- TRANSPARENCY

Enables data-driven operations where all information is traceable and monitored, creating maximum transparency. This makes it easier to detect anomalies, helping prevent fraud or asset loss. - DECISION SUPPORT

Provides a comprehensive view of financial and operational performance with customizable reports and real-time insights, eliminating the need for manual reporting. - COST SAVINGS

Reduces expenses by consolidating all enterprise management platforms into a single system and automating processes across the organization, minimizing manual work. - EFFICIENCY

Boosts performance by leveraging process automation and artificial intelligence to optimize manual, repetitive tasks that are prone to human error.

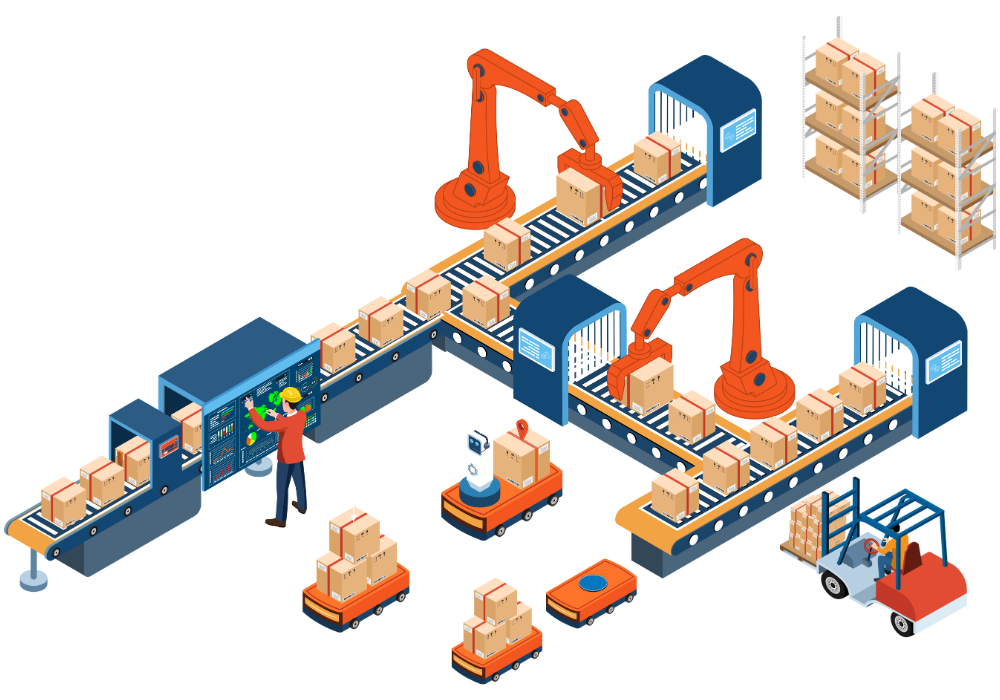

DEHA:ERP fits a wide range of manufacturing industries

Many manufacturing sectors have unique operational processes that require highly customizable management systems tailored to their specific needs. DEHA:ERP is designed to address management challenges across various industries. Below are some of the manufacturing industries where DEHA:ERP can effectively solve critical management issues.

Packaging & Labels

Electronic Components

Mechanical Engineering

Energy

Pharmaceuticals

Automotive

Plastics

Food & Beverage

Understanding Your Challenges

More than anyone, we understand the current management issues faced by manufacturing businesses in Vietnam.

Fragmented Data

Using multiple standalone software tools to manage operations leads to scattered data, making it difficult for managers to retrieve information and consolidate reports.

Manual Processes

Many management tasks are still handled manually, by entering data into Excel sheets or writing in notebooks. This increases the risk of errors and data loss, while also consuming significant time to keep information up to date.

Lack of Compatibility

Existing software often fails to align with the factory’s operating and production processes. As a result, only parts of it are utilized, while the rest revert to being managed manually through various other tools.

Efficient Management with DEHA:ERP

A feature-rich system that meets the in-depth and comprehensive management needs of manufacturing enterprises.

Production Management

Monitor and control the entire production process, from production planning, material requirements calculation, production scheduling, execution by work orders, to costing and multi-dimensional production result analysis through advanced reporting systems.

Quality

Management

Supports setting up quality inspection activities under various conditions across IQC, PQC, and OQC stages. Enables statistical analysis, defect rate evaluation, root cause tracking, and traceability, allowing for timely solutions to minimize errors.

Sales Management

Optimize the sales process from customer management, quotation handling, and order creation to customer care. Provides intuitive management reports, supports sales forecasting by period, and helps establish effective sales policies.

Logistics Management

Manage and optimize the transportation of goods. Supports internal fleet and outsourced vehicle management, including related costs such as fuel and maintenance. Ensures transparency and accuracy in calculating the cost of goods sold.

Warehouse Management

Manage warehouse operations and inventory control, supporting various import/export methods. Barcode technology integration eliminates manual processes, reduces inventory costs, and saves time on warehouse transactions.

Procurement Management

Design and control purchasing workflows by project, department, or phase. Manage supplier information and evaluations, with analytical purchasing reports across multiple data dimensions.

Finance & Accounting

Automate accounting operations, control cash flow and budgets, manage production costs, and calculate costing using multiple methods. Accurately analyze and report financial data with full transparency.

Human Resources & Administration

Streamline processes from personnel and payroll management to organization structure, recruitment, and training. Empower managers with a comprehensive view of actual workforce situations and HR quality.

Elevate Your Management with DEHA:ERP

Implementing DEHA:ERP brings practical, measurable benefits to manufacturing enterprises.

COMPREHENSIVE ENTERPRISE MANAGEMENT

By managing all activities on a single unified platform, DEHA:ERP enables manufacturers to automate organizational processes, improve operational efficiency, enhance flexibility, and minimize errors.

REDUCED PRODUCTION COSTS

DEHA:ERP establishes standardized workflows to closely monitor progress, output, and material consumption, thereby optimizing production time and reducing risks and errors on the shop floor.

ACCURATE INVENTORY CONTROL

Seamlessly connected with other modules in the system, DEHA:ERP allows precise management of inventory status and optimization of stock levels, ensuring timely production and delivery.

DATA TRANSPARENCY

Operate with data-driven processes where every piece of data is traceable and monitored. This maximizes transparency, making it easier to detect irregularities, thus limiting fraud and asset loss.

Discover Real Digital Transformation Stories

Digital Camera Factory

Located in Long Thanh Industrial Park, this digital camera manufacturer deployed an ERP system to tackle challenges related to productivity and data transparency.

Decal Manufacturing Plant

At An Khanh Industrial Park, this decal manufacturer implemented an ERP management system to boost operational efficiency and move toward building a smart factory.

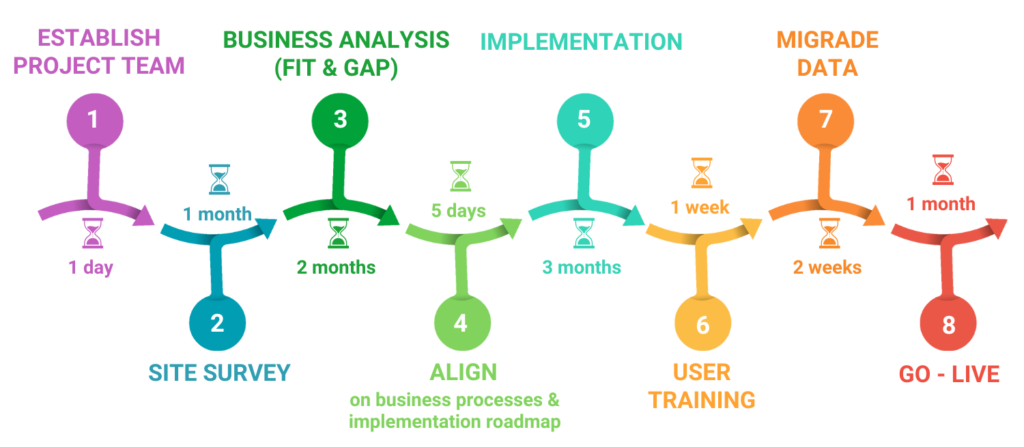

Professional Smart Factory Digital Transformation Roadmap

Start a new project

Briefly describe your project and needs so we can provide quick support.

Experienced Digital Transformation Experts

- Digital Transformation consultant and IFS Cloud implementation specialist in Vietnam with 15 years of experience.

- He has helped Vietnamese and Japanese businesses achieve successful digital transformation, especially in manufacturing sectors such as packaging, electronic devices, and electronic components.

- Expert in implementing IFS ERP Supply Chain Planning (SCP) systems with nearly 10 years of hands-on experience.

- He specializes in consulting and analyzing manufacturing operations, supporting businesses in moving from manual management models to modern systems such as ERP, MES, and WMS.

- Holder of PSM1, PSM2, and DX certifications.

- Specialist in deploying IFS ERP Manufacturing Management Systems with close to 10 years of experience.

- Certified with prestigious IT professional credentials including PSD, PSM1, PSM2, and CMMI. Well-versed in SCADA, MES, ERP, and industrial data communication protocols.

- Skilled in applying AI, Big Data, and Cloud in IIoT environments.