DEHA:M

Manufacturing Management

for

Factory

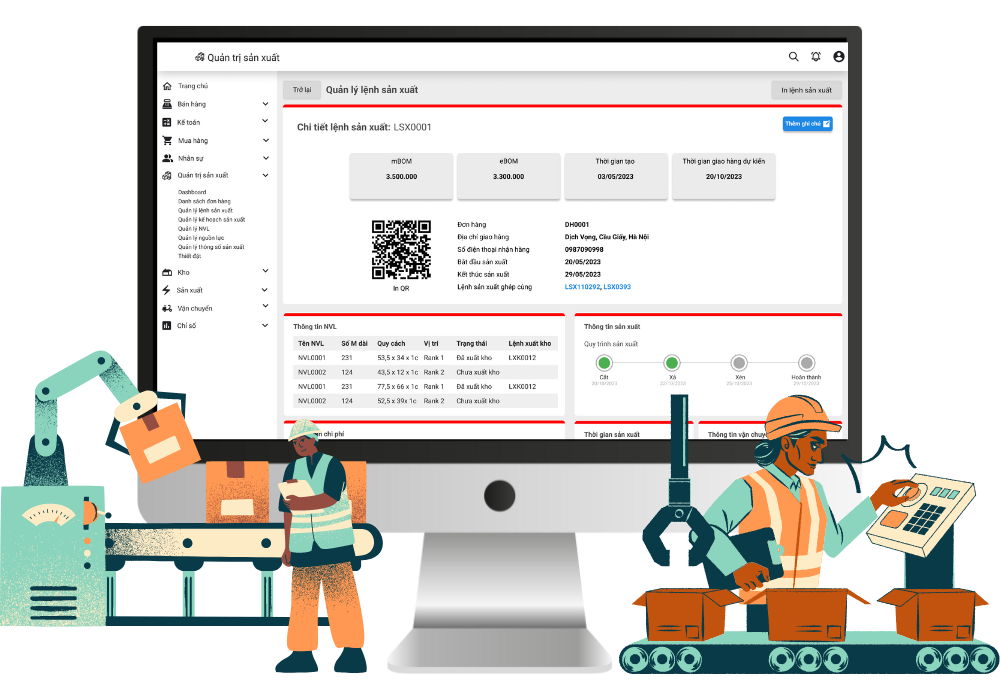

The Manufacturing Management module is part of the custom-designed ERP system tailored for manufacturing enterprises:

- Automatically collects actual production data and automatically calculates the BOM during production planning.

- Supports costing of individual components within the BOM.

- Enables real-time production progress tracking through information transmission via QR code scanning on the production line.

DEHA:M Features Empower Efficient Production Management

With two specialized production management modules designed for both office staff and factory floor personnel, the DEHA:M solution enables comprehensive, seamless, synchronized, and efficient production management.

Production Management Module

- Office Operations -

Efficiently manage production activities with features specifically designed for office teams, such as:

Production Management Module

- Factory Operations -

Comprehensively manage actual ongoing production processes with features tailored specifically for the factory floor:

PRODUCTION ORDER MANAGEMENT

Enables the creation and management of specific production orders. Each order includes information on the product to be manufactured, quantity, completion time, required materials, and associated costs.

PRODUCTION MANAGEMENT

Monitor, collect, and analyze data on product output. Compare input materials and finished products to calculate consumption and waste rates.

PRODUCTION PLANNING MANAGEMENT

Allows users to create, adjust, and manage the company’s production plans. Planning can be based on sales orders, production projects, or fixed production cycles, providing a comprehensive view of the production schedule.

ENVIRONMENT MANAGEMENT

Track and control production environment conditions such as temperature, pressure, and humidity.

PRODUCT & MATERIAL MANAGEMENT

Enables management of the company’s product catalog. Products can be added, edited, or removed, with detailed information such as name, description, pricing, and other relevant data.

QUALITY MANAGEMENT

Monitor and record the number of defective or non-conforming products during production. Classify and log detailed information about defects for root cause analysis and continuous quality improvement.

RESOURCE MANAGEMENT

Manages the resources required for production processes, including labor, machinery, and equipment. This helps track resource usage and ensures availability when needed for production.

EQUIPMENT MANAGEMENT

Track machine and equipment downtime. Record the reasons for stoppages and compile statistical reports based on this data.

PRODUCTION PARAMETER MANAGEMENT

Allows middle managers or executives to define and monitor production parameters that are automatically calculated by the system. It also enables the setup of alerts when parameters exceed predefined thresholds.

ABNORMALITY ALERTS

Aggregate production performance and progress data by shift, display it in the factory area, and generate alerts for anomalies.

Comprehensive Production Management with DEHA:M

The DEHA:M module enables seamless management of all aspects related to factory production operations.

The user interface is designed to be friendly and accessible across devices—including desktop computers, smartphones, tablets, and factory TV screens.

Take a look at the images below to see real examples of some key features in this module.

Benefits of Using the DEHA:M Solution

+75%

Production productivity

+25%

Product quality

-35%

Operating costs

-85%

Waste reduction

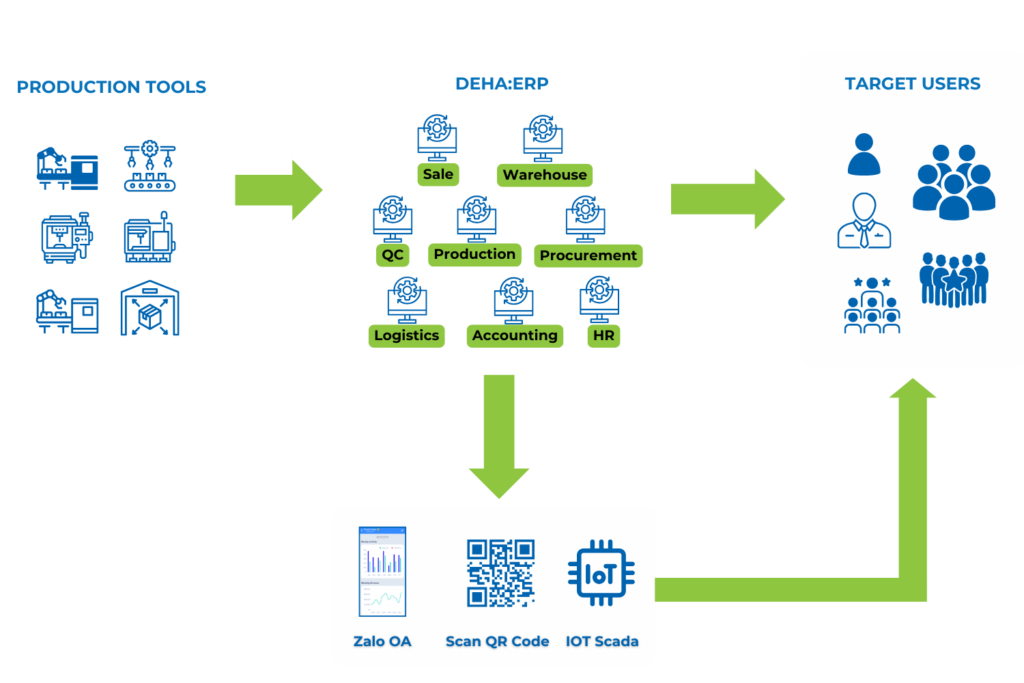

x10 Efficiency with DEHA:ERP

Going beyond production management with the DEHA:M module, you can operate your entire manufacturing process with the comprehensive factory management solution DEHA:ERP.

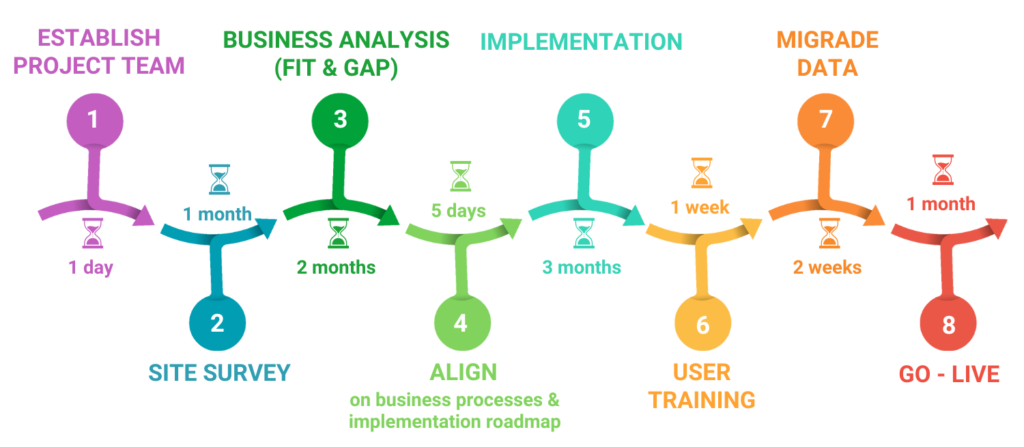

Professional Smart Factory Digital Transformation Roadmap

Start a new project

Briefly describe your project and needs so we can provide quick support.

Experienced Digital Transformation Experts

- Digital Transformation consultant and IFS Cloud implementation specialist in Vietnam with 15 years of experience.

- He has helped Vietnamese and Japanese businesses achieve successful digital transformation, especially in manufacturing sectors such as packaging, electronic devices, and electronic components.

- Expert in implementing IFS ERP Supply Chain Planning (SCP) systems with nearly 10 years of hands-on experience.

- He specializes in consulting and analyzing manufacturing operations, supporting businesses in moving from manual management models to modern systems such as ERP, MES, and WMS.

- Holder of PSM1, PSM2, and DX certifications.

- Specialist in deploying IFS ERP Manufacturing Management Systems with close to 10 years of experience.

- Certified with prestigious IT professional credentials including PSD, PSM1, PSM2, and CMMI.

- Well-versed in SCADA, MES, ERP, and industrial data communication protocols.

- Skilled in applying AI, Big Data, and Cloud in IIoT environments.