DEHA:QC

Quality Management for

Manufacturing Businesses

The Quality Management module is part of a tailor-made ERP system designed specifically for manufacturers. It supports all three key stages of comprehensive quality control: IQC (Incoming Quality Control), PQC (Process Quality Control), and OQC (Outgoing Quality Control).

Effectively Solve Quality Management Challenges with DEHA:QC

Here are 5 powerful quality management functions to help manufacturers overcome common quality issues.

QUALITY ASSURANCE (QA)

Set up checklists including inspection schedules and procedures for different groups of raw materials. Manage all quality-related documentation and workflows.

QUALITY INSPECTION

Support all three key quality control stages: IQC (Incoming), PQC (Process), and OQC (Outgoing). Ensure inspection of the entire production process.

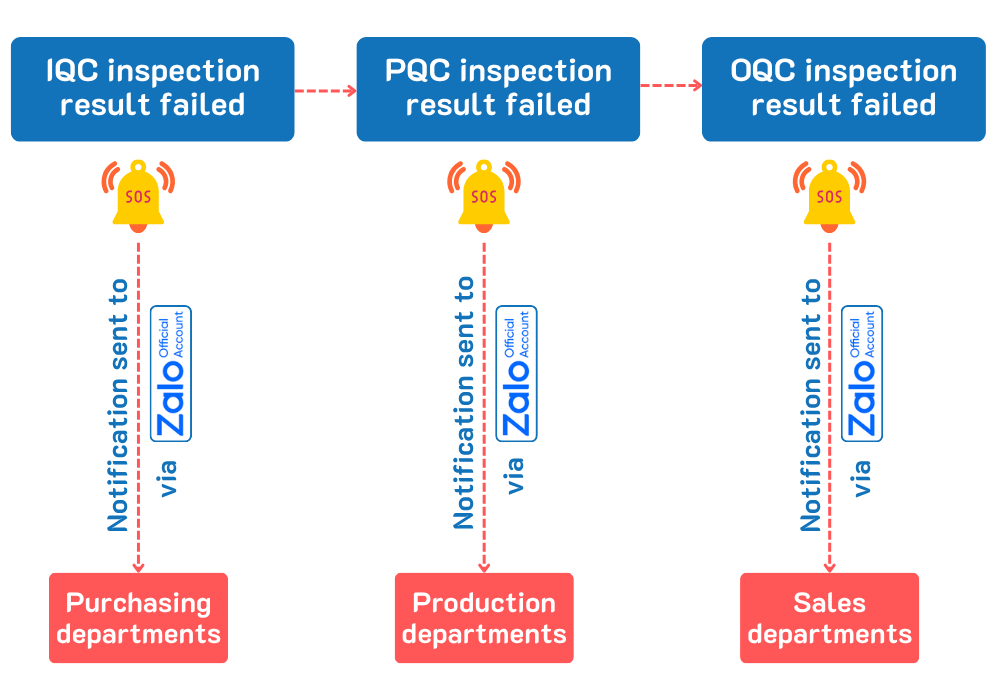

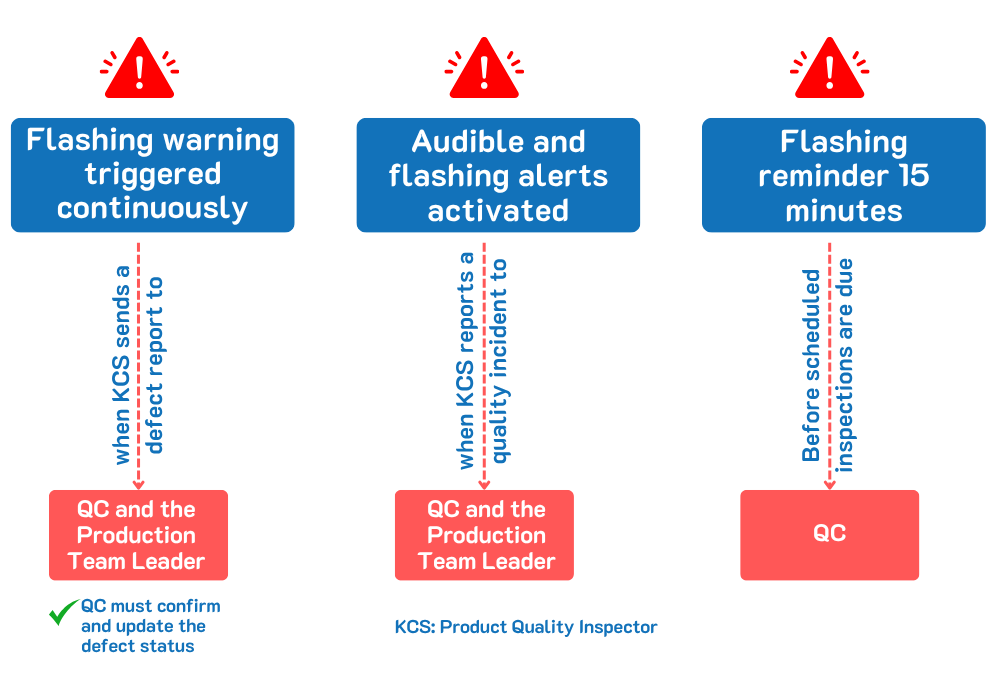

ALERTS & NOTIFICATIONS MANAGEMENT

Configure notification scenarios to instantly alert responsible personnel or departments when quality issues occur. Set up warning signals (blinking lights, alarm sounds) for critical quality-related incidents

DEFECT CLASSIFICATION & MANAGEMENT

Classify defects and incidents by severity. Record detailed defect information for analysis and resolution.

QUALITY REPORTING & ANALYTICS

Generate quality reports for products and services. Analyze quality data to support better decision-making and continuous improvement.

Comprehensive Quality Alerts, Tailored for Your Factory

The alert and notification management feature in DEHA:QC is comprehensively designed based on your factory’s actual quality control processes, ensuring smooth and worry free operations.

IQC (Incoming Quality Control) | PQC (Process Quality Control) | OQC (Outgoing Quality Control

Key Benefits of Using DEHA:QC

IMPROVED QUALITY

Ensure consistent production standards, minimize errors, and detect issues early in the manufacturing process.

COST SAVINGS

High product quality reduces the need for re-inspections and warranty claims. The system also helps optimize production resources.

ENHANCED EXPERIENCE

Deliver high-quality, defect-free products to your customers. Consistent quality builds trust and long-term customer loyalty.

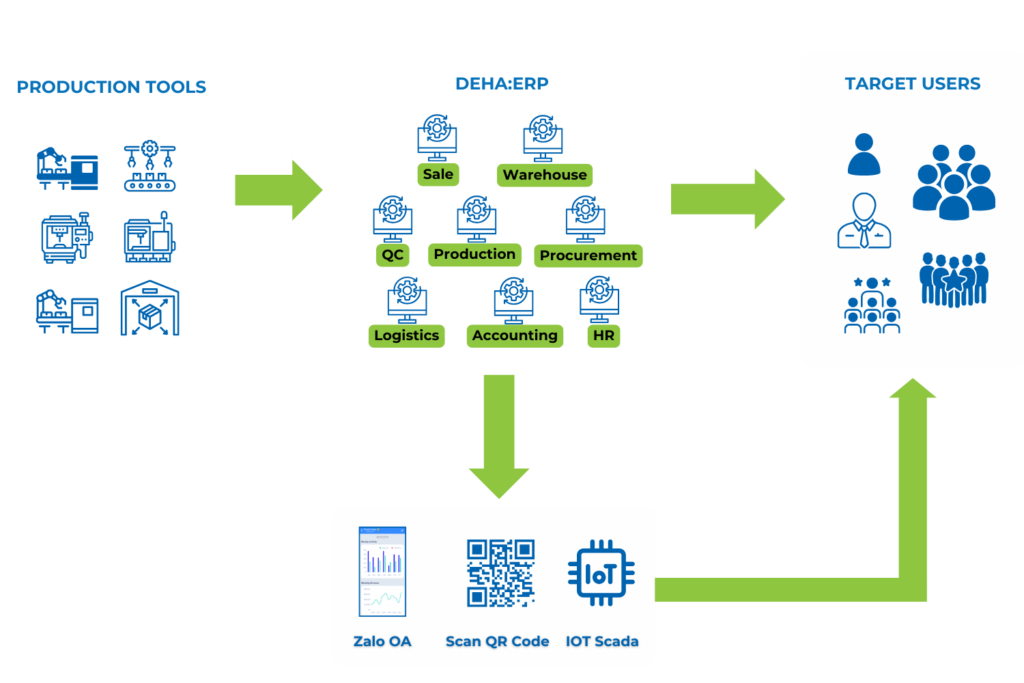

X10 Efficiency with DEHA:ERP

Going beyond production management with the DEHA:QC module, you can operate your entire manufacturing process with the comprehensive factory management solution DEHA:ERP.

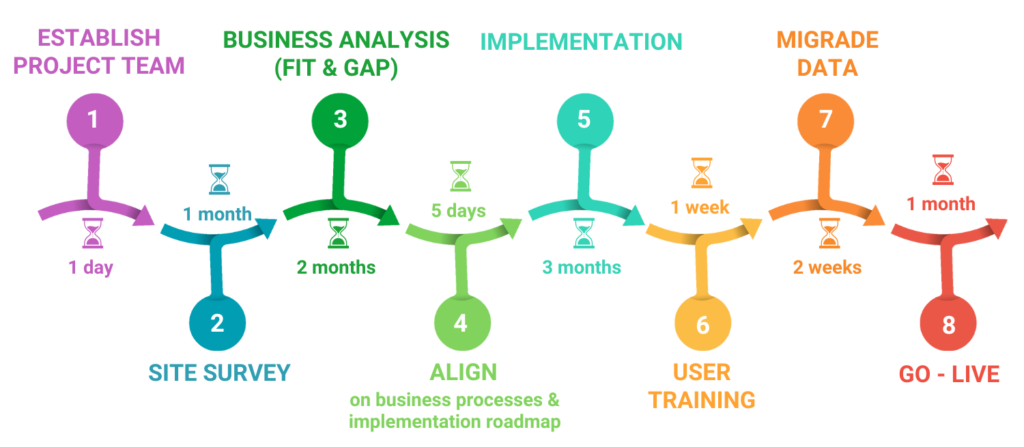

Professional Smart Factory Digital Transformation Roadmap

Start a new project

Briefly describe your project and needs so we can provide quick support.

Experienced Digital Transformation Experts

- Digital Transformation consultant and IFS Cloud implementation specialist in Vietnam with 15 years of experience.

- He has helped Vietnamese and Japanese businesses achieve successful digital transformation, especially in manufacturing sectors such as packaging, electronic devices, and electronic components.

- Expert in implementing IFS ERP Supply Chain Planning (SCP) systems with nearly 10 years of hands-on experience.

- He specializes in consulting and analyzing manufacturing operations, supporting businesses in moving from manual management models to modern systems such as ERP, MES, and WMS.

- Holder of PSM1, PSM2, and DX certifications.

- Specialist in deploying IFS ERP Manufacturing Management Systems with close to 10 years of experience.

- Certified with prestigious IT professional credentials including PSD, PSM1, PSM2, and CMMI. Well-versed in SCADA, MES, ERP, and industrial data communication protocols.

- Skilled in applying AI, Big Data, and Cloud in IIoT environments.