Specialized ERP for Electronics Manufacturers

- Increase productivity, reduce waste, ensure quality & compliance.

- Meet delivery deadlines, reduce inventory of costly components, control production costs, and enhance competitiveness.

Understanding Your Challenges

We truly understand the production management challenges faced by electronics manufacturers in Vietnam.

Production Order Confusion

- This is a common issue for manufacturing businesses when there is a sudden surge in orders.

- Adjusting and controlling processes per order, along with the complexity of BOM management, leads to difficulties in cost calculation and production cost control.

Lack of Production Process Synchronization

- Manual process management leads to fragmented data, causing delays across the entire inbound and outbound workflow and making it difficult to monitor production status by individual orders.

Material Management Disorder

- A large and diverse list of raw materials (RM) presents ongoing challenges in tracking and managing input quantities, while ensuring that components and parts are used according to production requirements.

- Without a proper material management system, businesses face shortages or excess inventory, leading to costly storage expenses.

No Product Traceability

- Unable to trace purchasing history or supplier information when low-quality materials are detected.

- No tracking or management of incoming material lists, and poor allocation of components and parts according to production requirements.

7 Outstanding Features of ERP for the Electronics Components Industry

An ERP system specifically designed for the electronics components industry includes management features tailored to its unique operational needs. This delivers superior efficiency that standard ERP systems cannot achieve.

Production Planning & Scheduling

- Plan and create production orders for finished goods and multiple workshops.

- Monitor product information, output, and completion time.

- Track material consumption, production processes, and output at each stage.

Inventory Management

- Track inbound, outbound, and on-hand stock using Barcode/RFID technology.

- Manage detailed inventory from raw material warehouses to finished goods, with multiple units of measure.

- Support complete batch-based inventory control, enabling full traceability.

- Generate reports on max/min stock levels, inventory aging, stock movement, and inventory value analysis.

Material Allocation Management

- Accurately allocate materials to each workshop, production line, and machine.

- Manage material quantities and consumption rates.

Quality Management

- Control the quality of raw materials, semi-finished products, and finished goods.

- Monitor and record quality parameters throughout the production process.

- Consolidate and analyze causes and frequency of defective or low-quality products.

Product Traceability

- Support traceability by raw materials, production processes, and assembly – packaging stages.

- Enable traceability using AI-integrated industrial image processing technology.

Cost Control & Product Costing

- Consolidate all production-related costs (materials, labor, overhead, etc.) for cost allocation.

- Support cost allocation based on various criteria, serving as a basis for product pricing.

Procurement Management

- Manage purchase requisitions with data inherited from inventory management.

- Manage supplier lists and quotations.

- Report, analyze, and forecast purchasing needs by period.

Standardized Processes – Surpassing Productivity

Using the ERP system developed exclusively by DEHA Digital Solutions for the electronics components industry will deliver superior management efficiency.

+30%

Production productivity

+25%

Product quality

-20%

Material Cost

-85%

Waste reduction

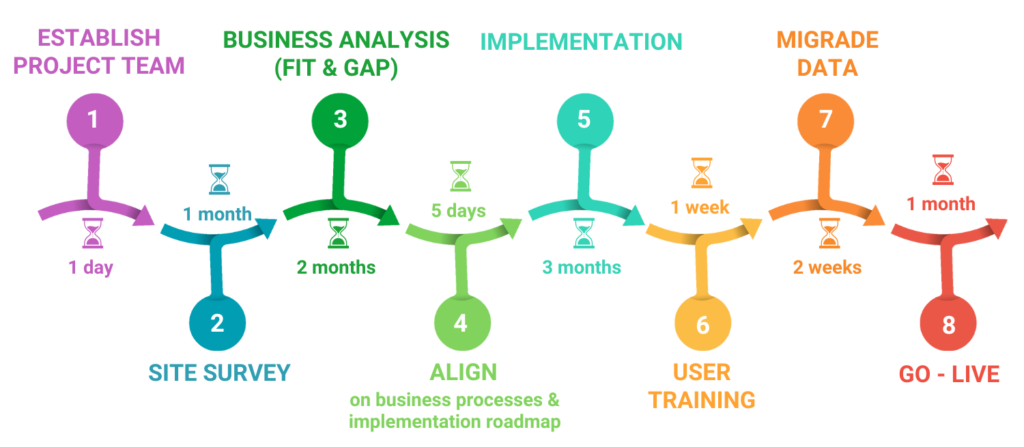

Professional Smart Factory Digital Transformation Roadmap

Start a new project

Briefly describe your project and needs so we can provide quick support.

Experienced Digital Transformation Experts

- Digital Transformation consultant and IFS Cloud implementation specialist in Vietnam with 15 years of experience.

- He has helped Vietnamese and Japanese businesses achieve successful digital transformation, especially in manufacturing sectors such as packaging, electronic devices, and electronic components.

- Expert in implementing IFS ERP Supply Chain Planning (SCP) systems with nearly 10 years of hands-on experience.

- He specializes in consulting and analyzing manufacturing operations, supporting businesses in moving from manual management models to modern systems such as ERP, MES, and WMS.

- Holder of PSM1, PSM2, and DX certifications.

- Specialist in deploying IFS ERP Manufacturing Management Systems with close to 10 years of experience.

- Certified with prestigious IT professional credentials including PSD, PSM1, PSM2, and CMMI. Well-versed in SCADA, MES, ERP, and industrial data communication protocols.

- Skilled in applying AI, Big Data, and Cloud in IIoT environments.