DEHA:WM

Smart Warehouse for

Smarter Manufacturing

The Warehouse Management module is part of a custom-built ERP system designed specifically for manufacturing businesses:

Manage warehouse operations based on accurate, real-time data

QR code technology enables fast and simple traceability

7 Core Functions of the DEHA:WM Module

These 7 powerful warehouse management features help manufacturers overcome operational challenges and optimize warehouse efficiency.

PRODUCT MANAGEMENT

Manage essential product and raw material information. Set safety stock levels for each item and receive timely alerts to proactively reorder when inventory falls below threshold.

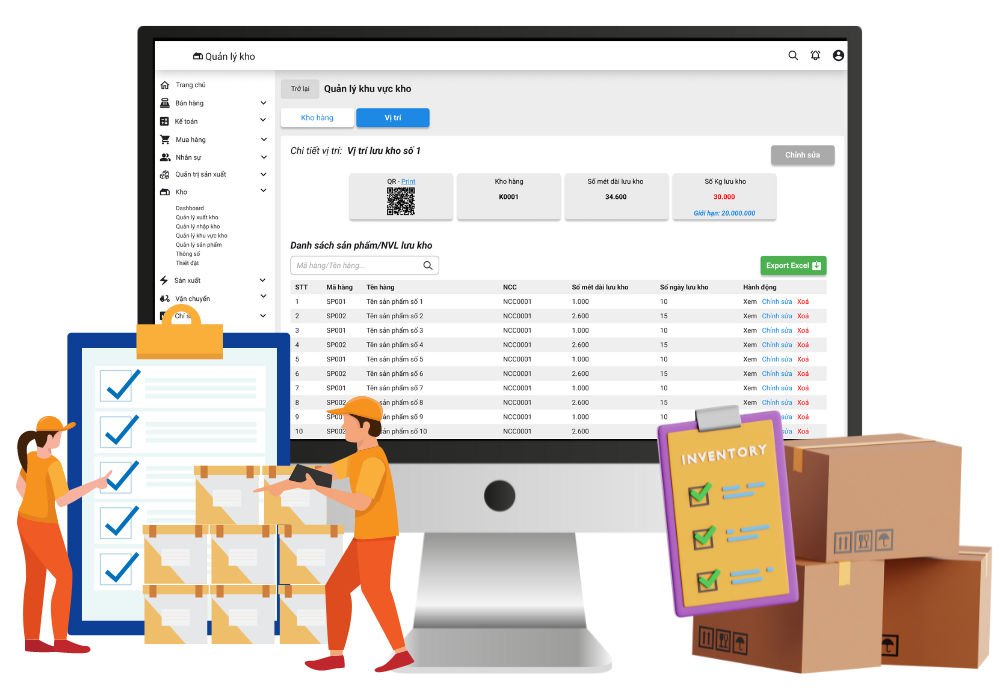

STORAGE ZONE MANAGEMENT

Utilize QR code technology to manage and assign specific storage locations based on criteria such as product type, batch number, production date, and dimensions, reducing time spent on stock checks and picking

INBOUND MANAGEMENT

Create and manage inbound plans and allocate resources upon purchase requests. Support verification and counting processes during goods receipt from suppliers.

OUTBOUND MANAGEMENT

Create outbound records based on production orders (with exact date and time), manage finished goods dispatches, and automatically generate outbound entries with “pending shipment” status.

WAREHOUSE METRICS

Automatically calculate key warehouse metrics such as inbound/outbound lead times to support production planning and inventory valuation.

SYSTEM CONFIGURATION

Configure and customize alerts, automatic purchase suggestions, and optimal sales recommendations. Set inventory valuation methods according to your business needs.

DASHBOARD

Visualize key warehouse data, including current and projected inventory levels, valuation, and stock movements—enabling real-time monitoring of warehouse KPIs.

Comprehensive Warehouse Management with DEHA:WM

The DEHA:WM module helps you manage every aspect of warehouse operations in your factory.

Its user-friendly interface is optimized for various devices, including desktop, mobile, and tablet.

Explore the feature screenshots below for a real-world look at what DEHA:WM can do.

Key Benefits of the DEHA:WM Module

PROACTIVE MATERIAL PLANNING

Thanks to safety stock settings, managers can proactively place orders, ensuring raw materials are always available for production.

EASY

ITEM LOCATING

Quickly find the exact location and retrieve the right products in the warehouse using QR codes, saving time and reducing errors.

MINIMIZED

WASTE

Effective product management ensures that near expiry materials are used in time, preventing forgotten stock and reducing unnecessary waste.

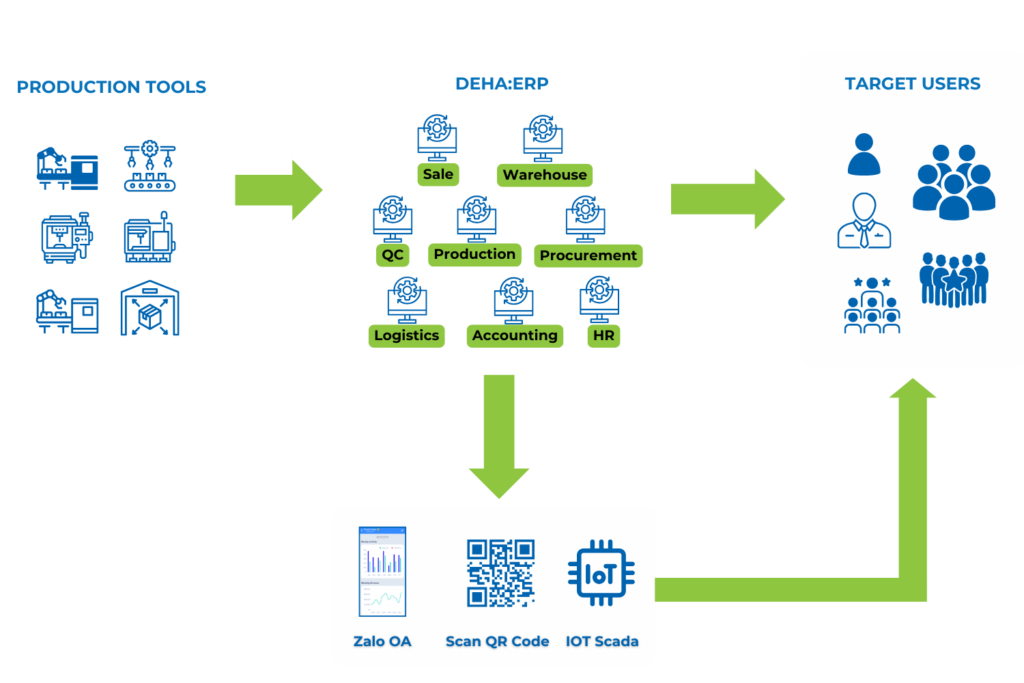

X10 Efficiency with DEHA:ERP

Going beyond production management with the DEHA:QC module, you can operate your entire manufacturing process with the comprehensive factory management solution — DEHA:ERP

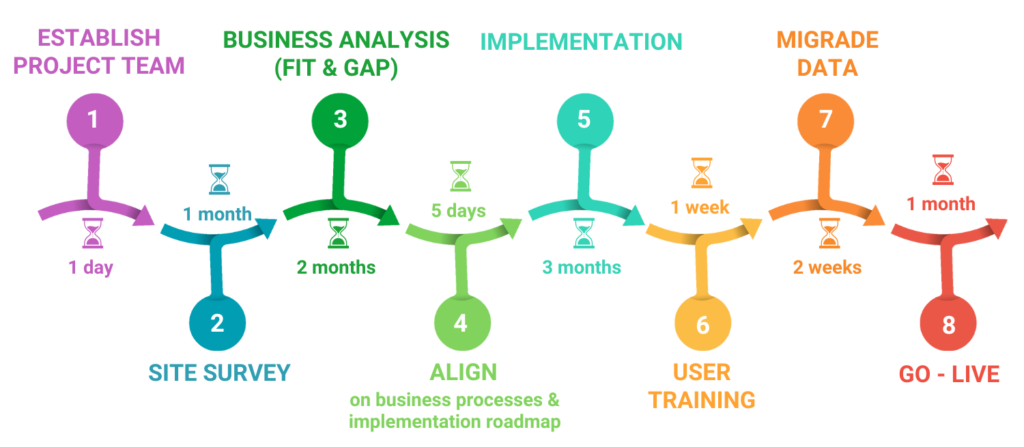

Professional Smart Factory Digital Transformation Roadmap

Start a new project

Briefly describe your project and needs so we can provide quick support.

Experienced Digital Transformation Experts

- Digital Transformation consultant and IFS Cloud implementation specialist in Vietnam with 15 years of experience.

- He has helped Vietnamese and Japanese businesses achieve successful digital transformation, especially in manufacturing sectors such as packaging, electronic devices, and electronic components.

- Expert in implementing IFS ERP Supply Chain Planning (SCP) systems with nearly 10 years of hands-on experience.

- He specializes in consulting and analyzing manufacturing operations, supporting businesses in moving from manual management models to modern systems such as ERP, MES, and WMS.

- Holder of PSM1, PSM2, and DX certifications.

- Specialist in deploying IFS ERP Manufacturing Management Systems with close to 10 years of experience.

- Certified with prestigious IT professional credentials including PSD, PSM1, PSM2, and CMMI. Well-versed in SCADA, MES, ERP, and industrial data communication protocols.

- Skilled in applying AI, Big Data, and Cloud in IIoT environments.