Customer Profile

The customer is a leading brand in Vietnam in smart warehouse storage solutions. They specialize in designing, manufacturing, and implementing industrial racking systems such as:

ASRS automated racks

Wi-Fi shuttle racks

Mobile racks

VNA racks

Steel pallets

Mezzanine floors, and more

All products are manufactured according to ISO 9001:2015, using Japanese-standard steel and designed following European FEM guidelines.

Customer Warehouse Management Challenges

Difficulty tracking inventory locations in diverse racking systems

Lack of synchronization between Factory – Warehouse – Sales departments

Time-consuming and error-prone stocktaking

Difficult to track product lifecycle (lot/batch/serial)

Insufficient data to optimize warehouse space

Lack of automation in goods receiving and dispatching

Slow reporting and absence of real-time data

Customer Requirements

Achieve >99% accurate inventory control

System must ensure:

Tracking by pallet/serial number

Instant recording for each inbound, outbound, and relocation transaction

System inventory equals actual inventory

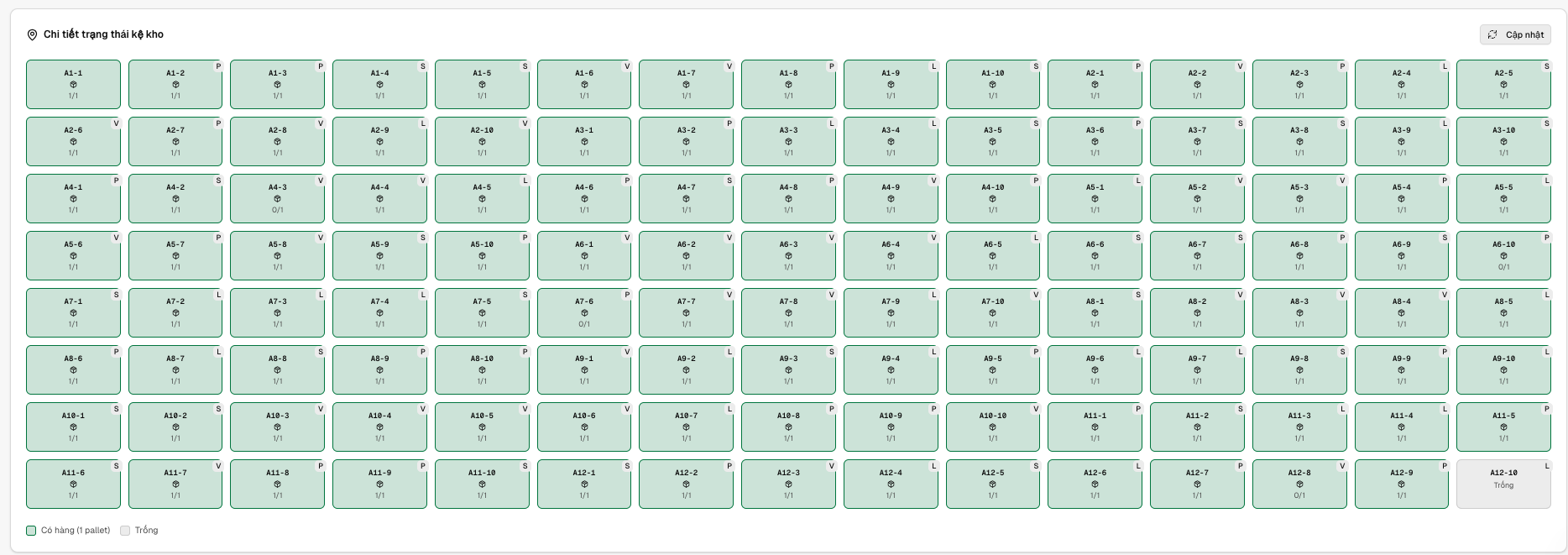

Location Management: automatic, logical, and optimized

A Smart WMS should:

Suggest storage locations based on product type, size, and turnover

Guide staff to the correct locations

Prevent errors between levels/slots/racks, especially in warehouses with multiple rack types or high storage

Identification Technology: Barcode/RFID

Fast scanning

Minimized errors

Automatic recording of all operations

Reduce human errors by 70–90%

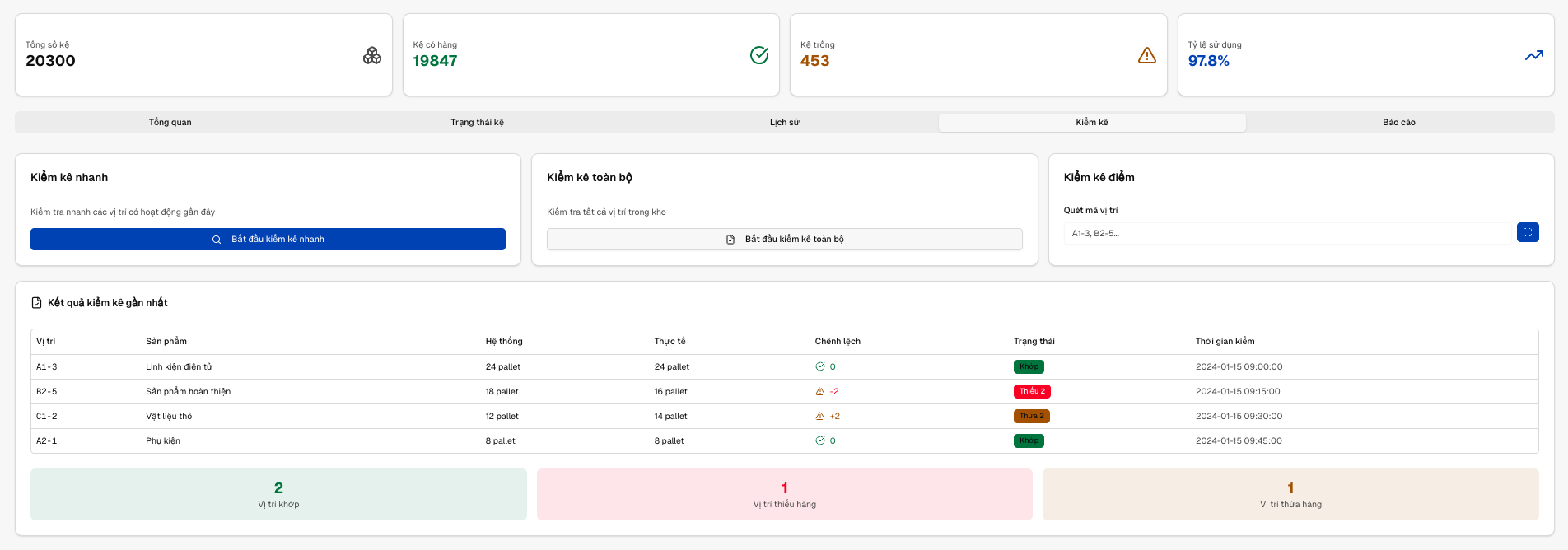

Smart Inventory Features

Cycle counting without affecting operations

Area-based stocktaking via app

Suggest inventory checks based on risk of discrepancies

Guided Operations for Warehouse Staff

Pick-by-line, Putaway-by-system

Integration with handheld devices, tablets, or voice picking

Critical for high racks or complex warehouse layouts

Overall Solution

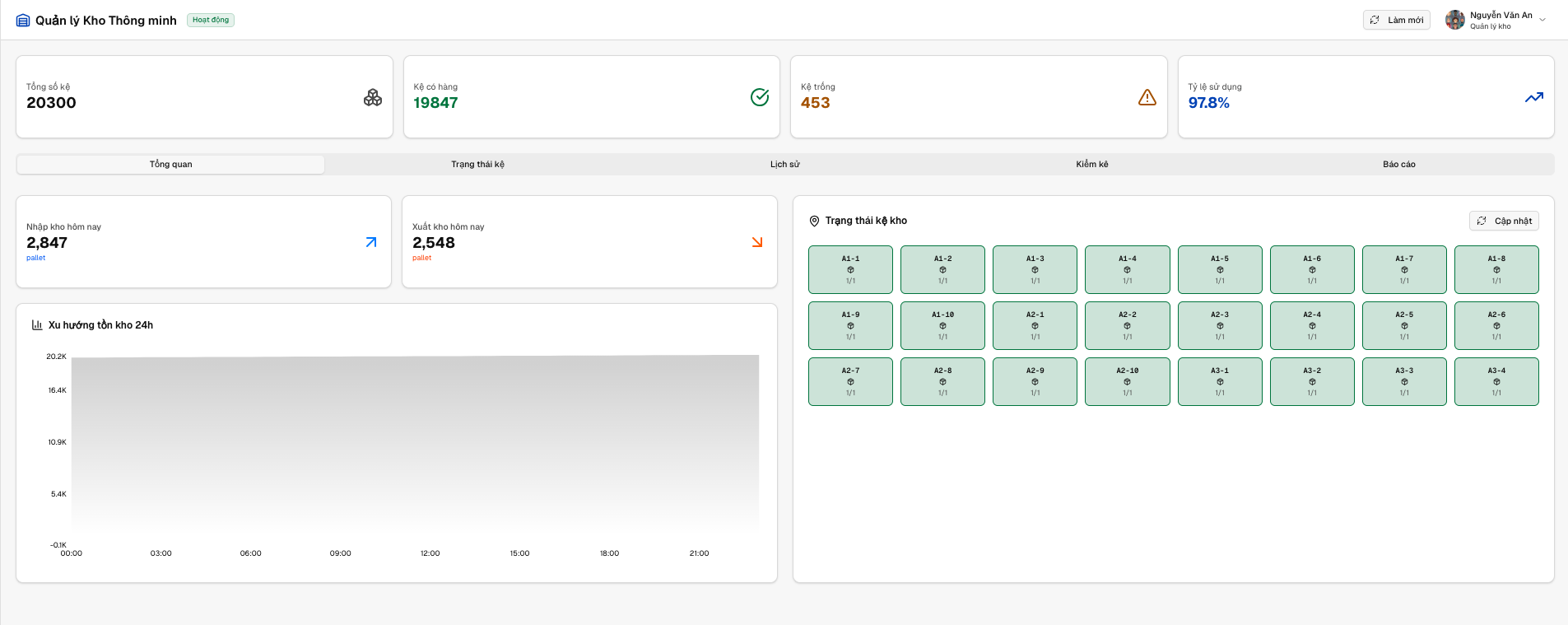

Comprehensive warehouse management

Detailed monitoring of rack and storage status

Intelligent stocktaking

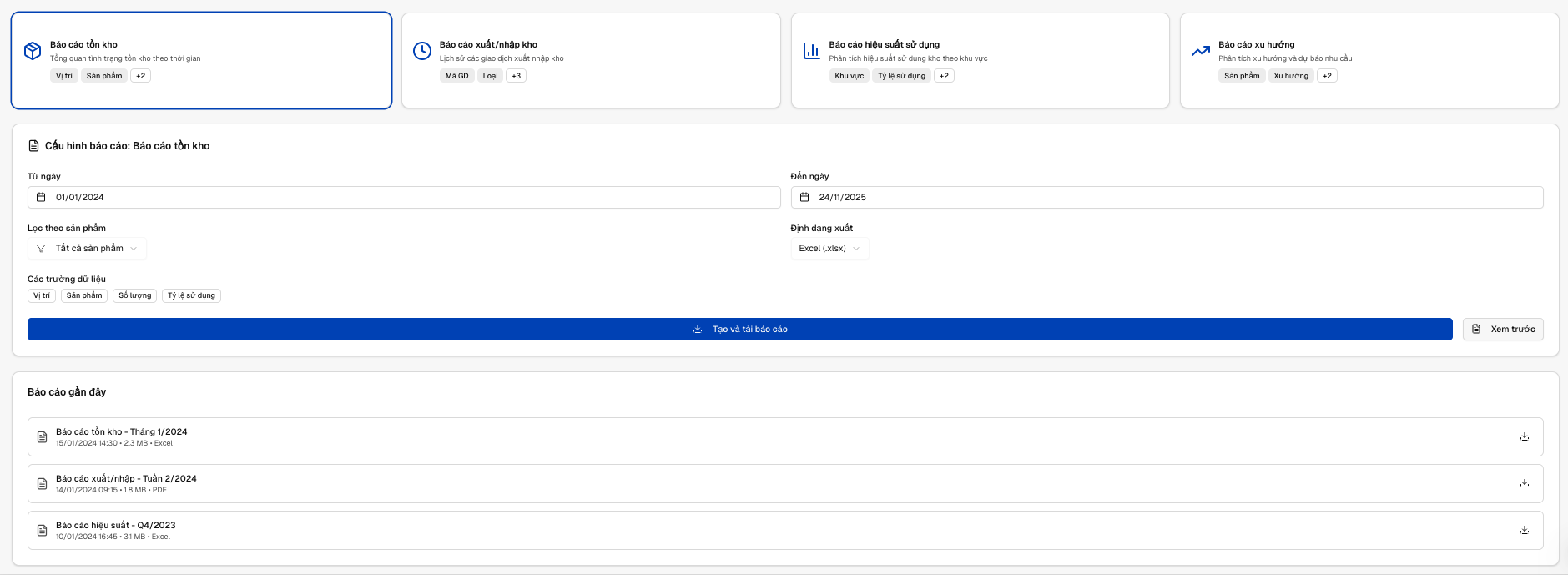

Reporting and analytics