IFS Cloud

ERP Consulting &

Implementation Solution

- A solution especially suitable for large-scale enterprises and FDI companies.

- A specialized cloud ERP designed for multiple industries, including manufacturing, energy, and defense.

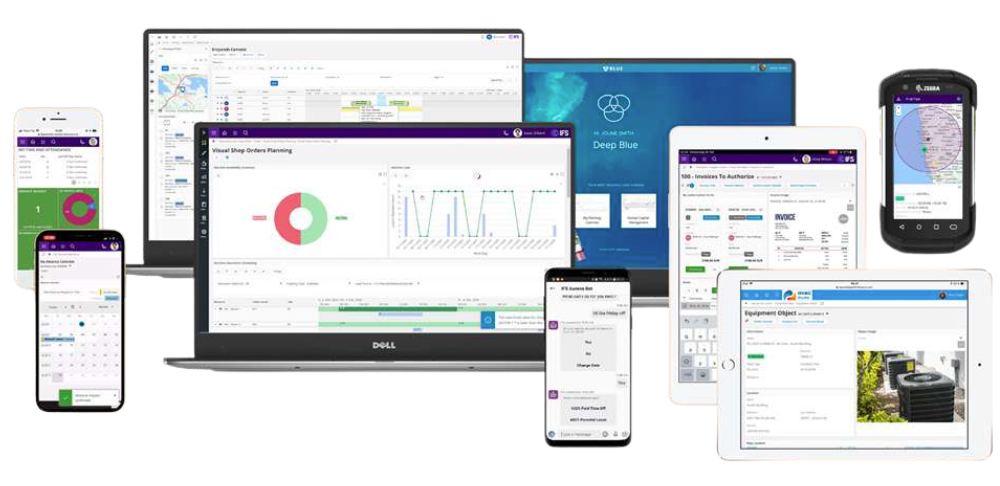

Manage your entire business efficiently on a single platform

IFS ERP is a smart, modern management platform that includes all the essential modules for key areas, especially manufacturing. This allows managers to start building the most suitable management solution for their business needs and easily add new functions as the company evolves and grows without the need to purchase or integrate additional systems.

3 Core Modules in IFS ERP to Build a Smart Factory

Let’s explore the key features of the three essential modules that any manufacturing plant needs.

Material Requirements Planning (MRP)

The MRP (Material Requirements Planning) module helps businesses optimize their production processes, from material planning to quality control. Key features include:

- Production planning

- Material management

- Production scheduling

- Quality control

- Production progress tracking

- Manufacturing cost management

Supply Chain Management (SCP)

The SCP (Supply Chain Planning) module ensures an efficient supply chain, from procurement to delivery. Key features include:

- Supply chain planning

- Inventory management

- Purchasing management

- Transportation & logistics management

- Order management

- Supplier collaboration

Financial Management (FIN)

The FIN (Finance) module offers comprehensive financial management tools that support data-driven decision-making. Key features include:

- General accounting

- Accounts receivable management

- Accounts payable management

- Budgeting & forecasting

- Cash flow management

- Cost & profitability accounting

- Financial reporting & analysis

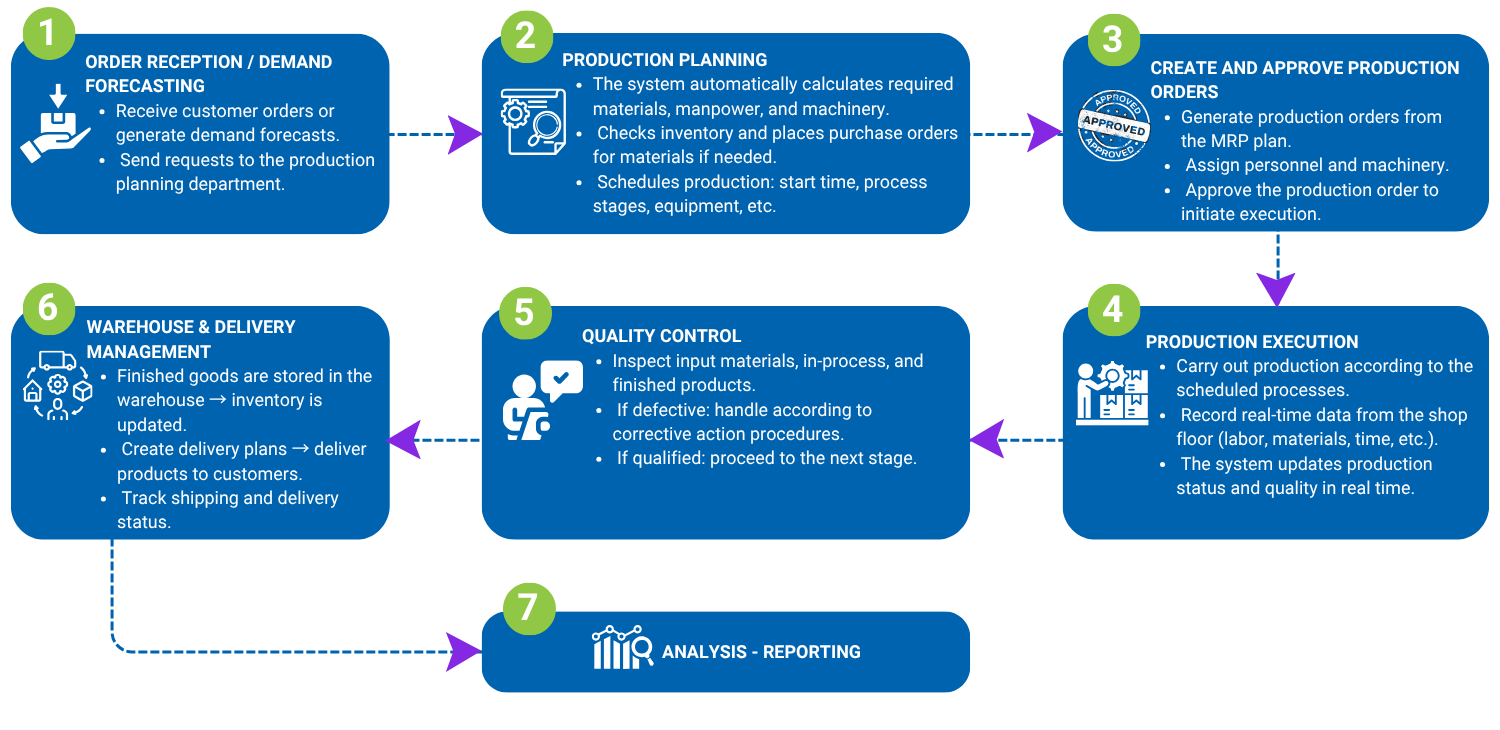

Basic Operational Flow Overview

IFS.ai - Integrating Industrial AI into Production Management

IFS.ai unleashes the power of embedded industrial AI to revolutionize how organizations operate. Here’s how IFS.ai harnesses industrial AI in production management through advanced algorithms.

Forecasting & Simulation

Using historical data to find patterns and enable simulation across the entire project life cycle.

- Automated risk analysis & mitigation.

- Simulation & evaluation of schedule & resources.

- Supply chain financial performance prediction.

Optimization

Take inputs such as goals, constraints, jobs, and resources to optimize outcomes.

- Balance schedules for costs & service level.

- Optimize contracts vs resources vs capacity.

- Optimize inventory for sustainability.

Anomaly Detection

Automatically identify anomalies through thresholds, business logic and real-time data.

- Proactive quality control & monitoring.

- Real-Time – anomaly correction.

- Predictive Maintenance.

Recommendation

Provide users with the insight they need and recommend corrective actions.

- Configuration to Improve production quality.

- Best inventory, production & resource usage.

- Sourcing & supplier decision support.

Contextual Knowledge

Analyze large volumes of data to deliver to users in a simple way.

- Easy assembly instructions & real time guidance.

- Analyze high value products & customers.

- Material shortage prediction & management.

Content Generation

Generate content throughout the project to support predictive budgeting and forecasting.

- Personalized training materials.

- Automated MRP proposals & control plans.

- Consistent dispatch documentation quality.

Why implement IFS ERP?

In 2024, IFS was recognized as a Customers’ Choice for Cloud ERP by Gartner® Peer Insights™. Additionally, IFS was named the No. 1 brand among the Top 100 Software Companies of 2024 by The Software Report. Here are key reasons why you should choose IFS ERP:

Efficient production control

Data is connected, captured, monitored, and synchronized from the shop floor in real time, supporting management and future business expansion.

Production schedule compliance

The system helps create and manage production plans, allowing businesses to promptly monitor manufacturing status, ensure on-time delivery, and enhance brand reputation.

Centralized resource management

Manage material consumption standards to minimize waste and prevent unexplained losses.

Process automation

Supports automating production reports, quality management, and improving OEE.

DEHA DS: A trusted partner for your business

In Vietnam, DEHA Digital Solutions (DEHA DS) is the reliable choice for businesses seeking IFS ERP solutions. We work hand-in-hand with iChengsi (an official IFS partner) to deliver a full suite of IFS Cloud services tailored to your enterprise needs.

System implementation

We build comprehensive, effective management systems for large-scale manufacturing enterprises. DEHA DS’s IFS Cloud implementation services include:

- Consulting and requirements analysis

System design and configuration - User training and support

- Post-implementation maintenance and assistance

System maintenance

Ensure your management system operates smoothly, stays up to date, and receives rapid technical support when needed. Our maintenance services include:

- Regular monitoring and maintenance

System updates and upgrades - Technical support and troubleshooting

- Advisory services and system optimization

System upgrades

Enable your business to transition to the latest version of IFS Cloud quickly, safely, and efficiently. Our upgrade services include:

- Upgrade assessment and planning

- Execution of the upgrade

- Testing and optimization

- Training and post-upgrade support

Build a Smart Factory with IFS ERP for Manufacturing

The Manufacturing module of IFS ERP is a comprehensive suite of functions that supports every stage of the production process from planning and execution to quality control and analysis of various manufacturing models. This module is especially well-suited for managing plants operating under Lean Manufacturing principles and mixed-mode production.

IFS ERP’s manufacturing module is ready to meet all your plant management needs with features such as:

- Sales and operations planning (S&OP)

- Material and production resource planning (MRP)

- Visual production planning and scheduling

- Product estimating management

- Configure-to-order and make-to-order manufacturing

- Quality management

- Management of process, discrete, and batch manufacturing

Case study Implementing IFS Cloud ERP in Vietnam

A Japanese brand specializing in manufacturing imaging and audio equipment with over 80 years of history, currently operating a factory in Vietnam.

Current management challenges:

The legacy management system could no longer meet the needs in Accounting and Production Planning.

Managers struggled to customize the software to fit current requirements. Handling customization requests took up to 2 months, causing significant issues in managing plant efficiency.

Very high costs for both use and customization.

A 100% Japanese-owned enterprise with a factory in Vietnam, specializing in manufacturing automotive engine parts and replacement accessories.

Current management challenges:

Their existing IFS ERP system was outdated, incurring high maintenance costs.

The management functionalities of IFS version 9.0 all required updates to operate more effectively.

Slow response and issue resolution times (around 2 months) with substantial costs.

IFS Cloud fits a wide range of manufacturing industries

Many manufacturing sectors have unique operational processes that require highly customizable management systems tailored to their specific needs. IFS Cloud is designed to address management challenges across various industries. Below are some of the manufacturing industries where IFS Cloud can effectively solve critical management issues.

Packaging & Labels

Electronic Components

Mechanical Engineering

Energy

Pharmaceuticals

Automotive

Plastics

Food & Beverage

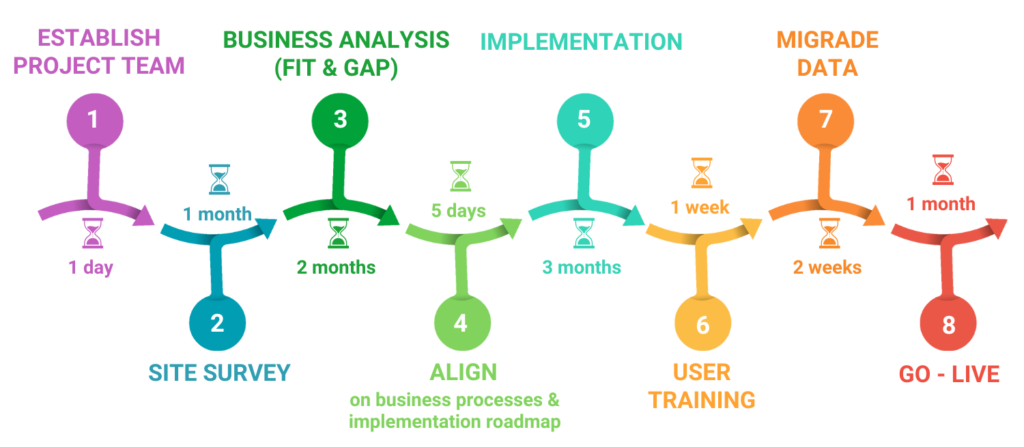

Professional Smart Factory Digital Transformation Roadmap

Start a new project

Briefly describe your project and needs so we can provide quick support.

Experienced Digital Transformation Experts

- Digital Transformation consultant and IFS Cloud implementation specialist in Vietnam with 15 years of experience.

- He has helped Vietnamese and Japanese businesses achieve successful digital transformation, especially in manufacturing sectors such as packaging, electronic devices, and electronic components.

- Expert in implementing IFS ERP Supply Chain Planning (SCP) systems with nearly 10 years of hands-on experience.

- He specializes in consulting and analyzing manufacturing operations, supporting businesses in moving from manual management models to modern systems such as ERP, MES, and WMS.

- Holder of PSM1, PSM2, and DX certifications.

- Specialist in deploying IFS ERP Manufacturing Management Systems with close to 10 years of experience.

- Certified with prestigious IT professional credentials including PSD, PSM1, PSM2, and CMMI. Well-versed in SCADA, MES, ERP, and industrial data communication protocols.

- Skilled in applying AI, Big Data, and Cloud in IIoT environments.