DQC (DEHA Quality control)

Industrial Vision Solution

Enhance Production Quality

- Eliminate manual inspection steps, reduce labor costs while maintaining or improving QC efficiency.

- Integrate reporting and data analytics.

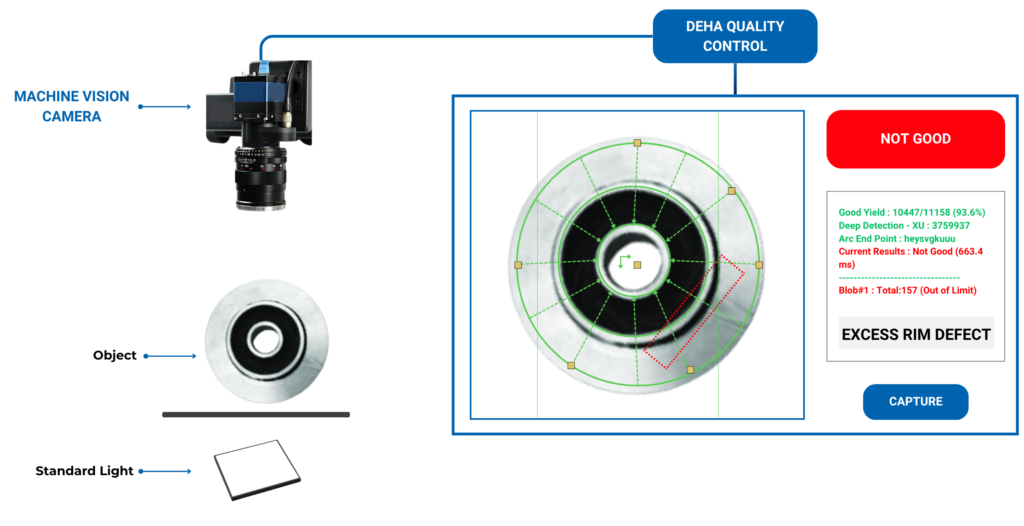

Overview of the DQC Solution DQC

DQC (DEHA Quality Control) is a quality control solution developed by DEHA Digital Solutions. It uses cameras combined with image processing algorithms (Machine Vision) to automatically inspect product quality within factories. With DQC, defects are detected automatically with high precision, dimensions are measured automatically, and shapes are checked against predefined standards. This helps manufacturers ensure consistent product quality, minimize human errors, and streamline the entire quality control process.

3 inspection categories DQC can handle

Structural shape

- Shape: Different from the design drawing, showing deformation or defects.

- Structure: Incorrect assembly, wrong positioning.

- Dimensions: Deviations from the specified description.

- Color: Deviations or unevenness.

- Design and printing: Different from the described specifications.

Surface condition

- Surface shape and tactile feel: Uneven, wrinkled, rough, damaged, or abnormal texture.

- Scratches: Presence of scratches or wear marks on the surface.

- Stains: Presence of stains or foreign objects on the surface.

Surface finishing quality

Product finishing: Presence of burrs, abnormal protrusions or indentations, or machining marks.

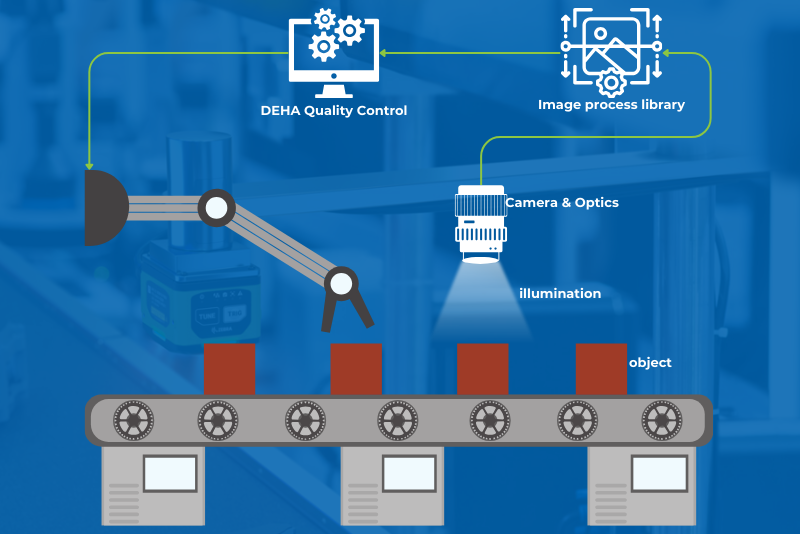

Supporting QC across diverse production models

The DQC solution can be applied to quality inspection in various manufacturing setups, especially when combined with robotic arms and kick units to automate the defect sorting process.

Production models with robotic arms

Production models with kick units

Case study of successful DQC application

With an impressive defect detection rate of 99%, the DQC solution ensures outstanding quality control in various manufacturing industries. This high level of accuracy helps reduce waste, improve operational efficiency, and protect brand reputation.

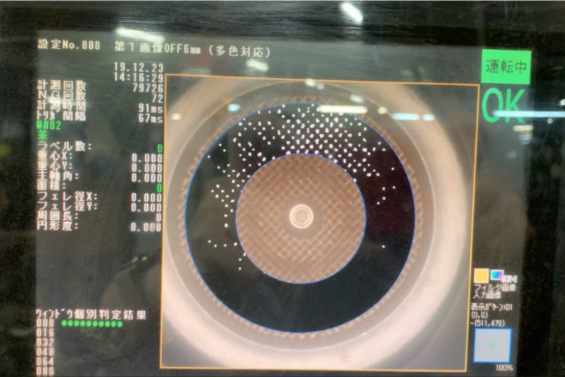

DQC system for inspecting grinding discs

- The DQC system is used to automate the product inspection process.

- Each production line is equipped with one inspection device.

- The checked parameters as well as the number of NG products are connected to the company’s manufacturing management system, helping to free up manpower in the QC department.

DQC system for inspecting pipe joint dimensions

- Uses cameras and lenses from a brand with similar functions but lower costs to measure the dimensions of the pipe joints as shown below.

- Integrated with the DQC system to increase inspection efficiency and connected to the factory’s warehouse management system to ensure consistent linkage.

Fits a wide range of manufacturing industries

The DQC solution delivers efficiency across various manufacturing industries, optimizing resources and driving high performance.

Electronics

- Inspect printed circuit boards (PCBs) to detect misplaced components and soldering defects.

- Check for cracks.

Pharmaceuticals

- Inspect size and shape of tablets; detect broken or discolored pills.

- Check for dust or contaminants on the tablet surface.

Automotive

- Inspect automotive parts for cracks and wear.

- Check paint quality and detect defects on car bodies.

Food

- Inspect color and shape of food products.

- Detect foreign objects and surface contamination.

Experienced team of experts

Feel completely confident when choosing the DQC solution by DEHA Digital Solutions, thanks to our team of experts with extensive hands-on experience in factory digital transformation and machine vision technology.

- 15 years of experience in consulting and implementing IT and digital transformation solutions for Vietnamese and Japanese enterprises.

- Specializes in advising manufacturing companies in various sectors such as packaging, electronic devices, and electronic components.

- Machine vision (DQC) expert with over 35 years of experience in factory quality control.

- Winner of the Excellence Award at the Image Processing Algorithm Inspection Contest held by the Precision Industry Association in 2005.

- Researcher at the Faculty of Engineering, Chukyo University (Japan).

Start a new project

Briefly describe your project and needs so we can provide quick support.