Customer Profile

An FDI enterprise from Hong Kong specializing in seafood processing, located in Tien Giang, Vietnam, with a workforce of 100–299 employees.

Current Production Management Challenges

Production management relies on Excel, leading to discrepancies, fragmented data, and lack of real-time visibility.

Unable to calculate output per worker → no productivity evaluation → inaccurate payroll.

No lot-level traceability.

Inability to determine shrinkage/yield at each processing stage (yield = the ratio of finished output to the input material for that stage).

QC forms are recorded manually, resulting in no real-time alerts.

Insufficient data for production planning.

No machine monitoring — no OEE tracking.

Slow reporting and lack of dashboards.

Difficulty meeting export audit requirements.

Customer Requirements

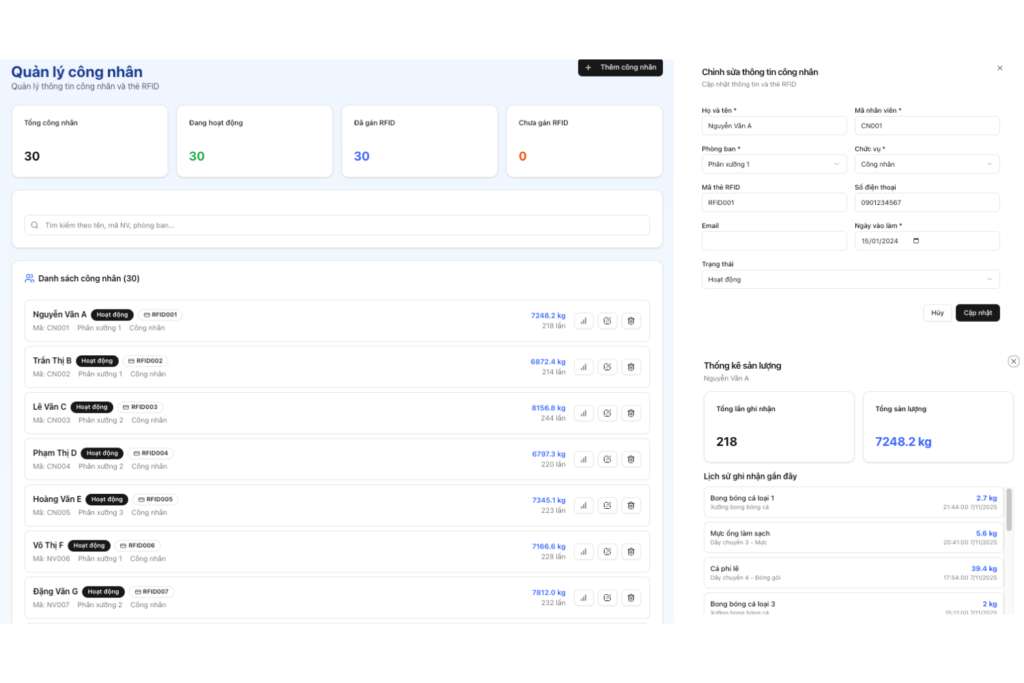

Each worker must be assigned a unique barcode. Their output will be weighed and automatically recorded in the management system.

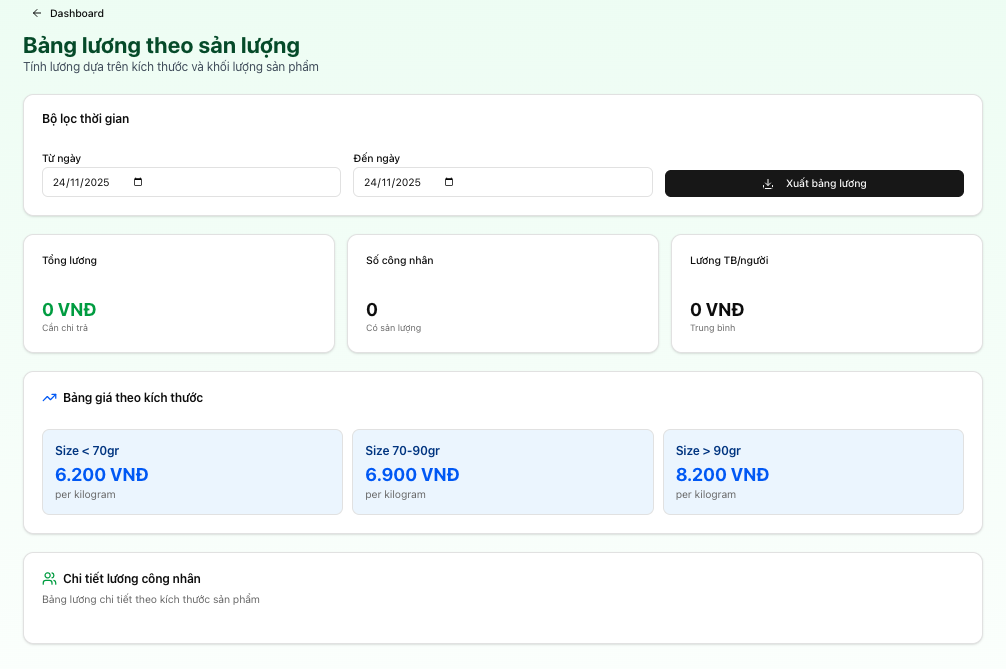

The customer aims to transition from manual recording to a digital system; the objective of capturing output is to calculate payroll accurately.

Requires consultation on hardware (must operate reliably in cold-storage environments with low temperatures and high humidity) and software.

Overall Solution

RFID-Based Output Management

RFID technology is used to capture worker-level production output as the basis for payroll. Each RFID tag contains:

A unique identifier (Employee_ID)

Job type / production team (optional)

Optional integration with attendance tracking

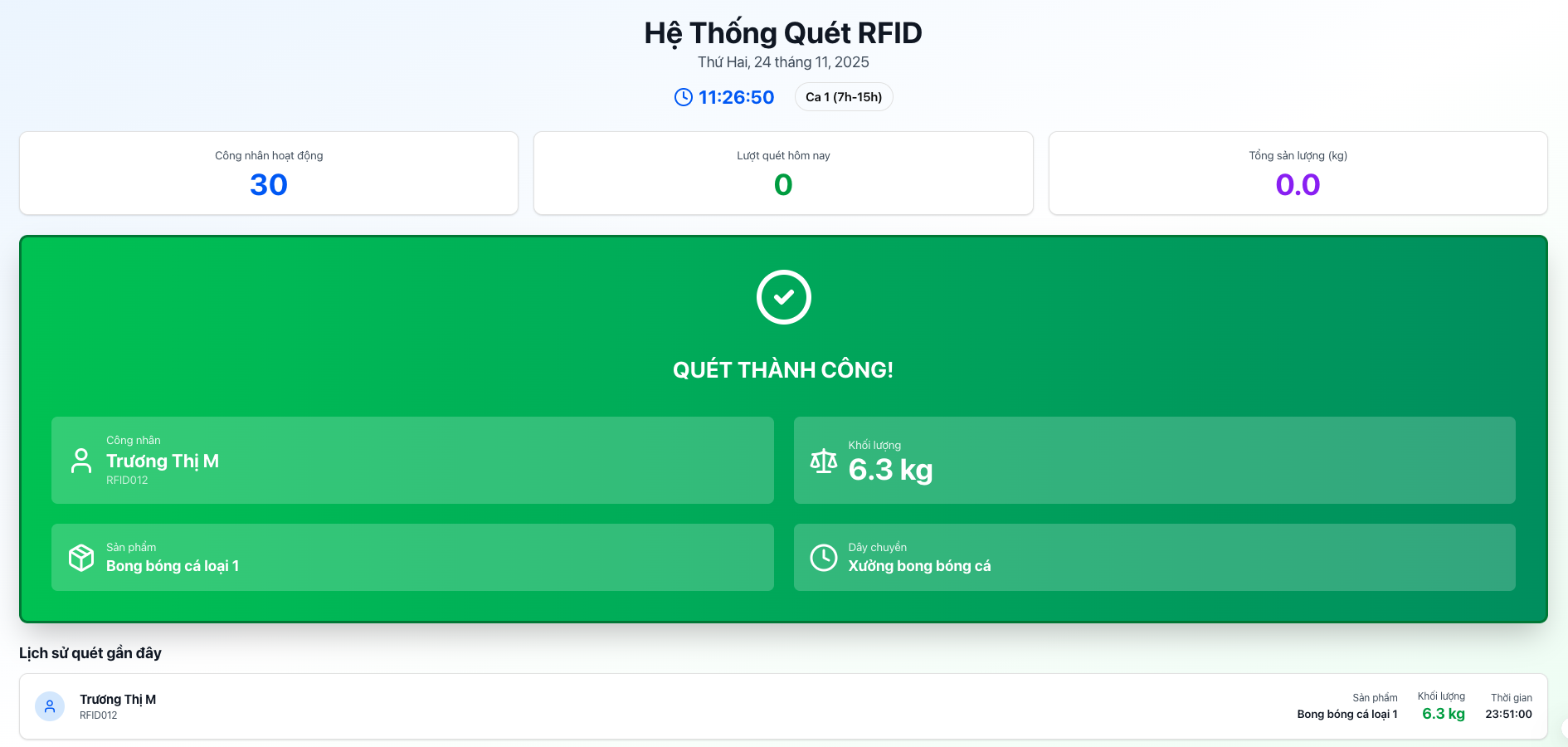

Production Output Recording Process (Process Flow)

Step 1: Workstation Check-In

When a worker arrives at the processing station, they scan their RFID tag at the reader. The MES system records:

Worker A starts working at the Fillet stage, Line 2

Start time

Material lot being processed

Step 2: Output Recording

When the worker completes a batch:

The product is placed on the scale/device

The scale automatically sends the weight to the MES

The MES associates the data with Worker A’s active session

→ Real-time, paperless data recording.

Step 3: Check-Out

At the end of the shift or when switching to another processing stage, the worker scans their RFID tag again to close the working session.

Worker Management

Payroll by Production Output

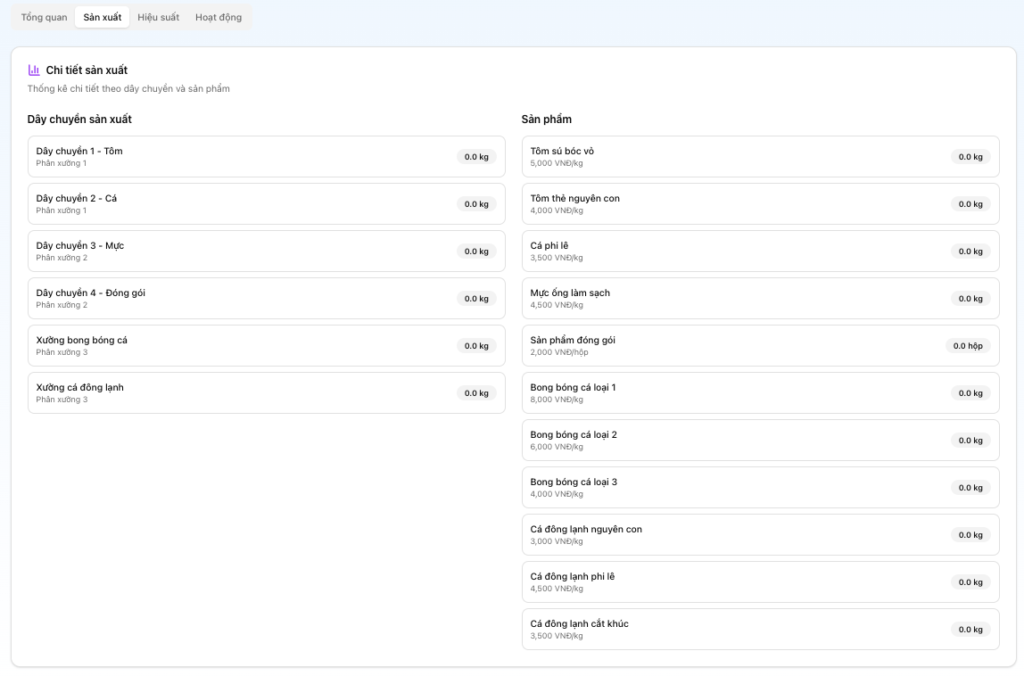

Production Management

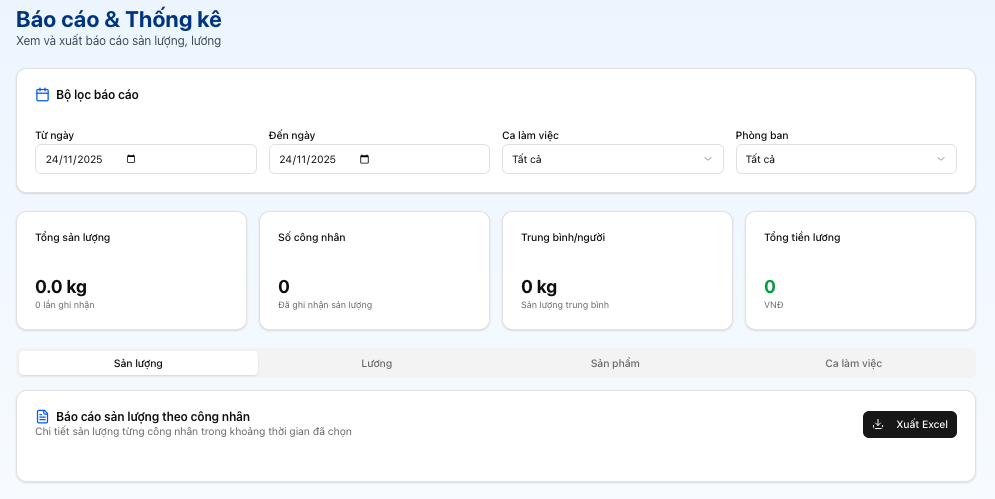

Reporting and Analytics