In agricultural product processing (fruits, grains, seeds, vegetables, herbs…), the drying stage directly affects:

Final product quality

Loss rate

Color, crispness, and flavor

Commercial value

Export potential

Energy costs

However, most factories today still use semi-manual drying methods, which carry significant risks. An intelligent drying monitoring and control system helps automate, standardize, and optimize the entire process.

Challenges in managing drying systems

Inaccurate control of temperature and humidity

Dryers are often operated based on workers’ perception → prone to errors. Even a few degrees or 5–10% difference in humidity can noticeably affect quality.Customer concerns

Inconsistent quality between batches: batch 1 looks perfect, batch 2 too dark, batch 3 over-dried… due to inability to control drying requirements for each type of raw material.

High energy waste

Dryers consume large amounts of electricity/fuel.

Lack of automatic optimization → high energy costs, increased production expenses.

Dependence on worker skill

Workers must:Monitor the machine

Rotate trays

Check moisture levels based on experience

Adjust temperature manually → labor-intensive and unstable results.

No data for traceability & improvement

Drying time, stage temperature, humidity charts, and alerts are often not recorded → impossible to identify the cause if the product is damaged.

No early warning for dryer malfunctions

Overheating, excess humidity, fan failures, or sensor errors can ruin the entire batch if not detected in time, causing significant losses.

Non-compliance with export requirements

Exported agricultural products (EU, US, Japan…) require drying logs to prove:

Products are free from mold due to under-drying

Proper heat treatment

Final moisture level meets standards

Without data → audits fail.

Overall Solution

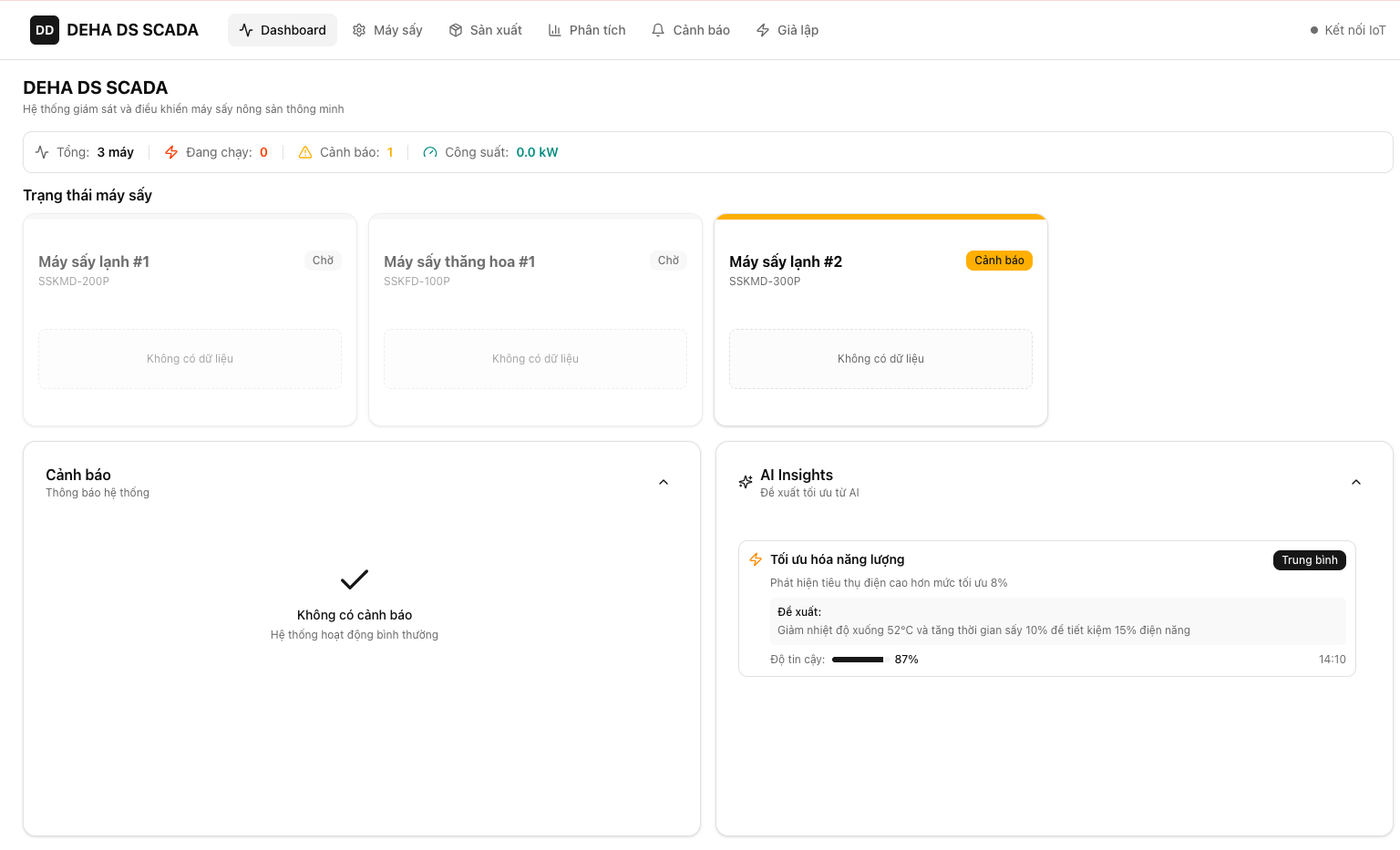

Dashboard

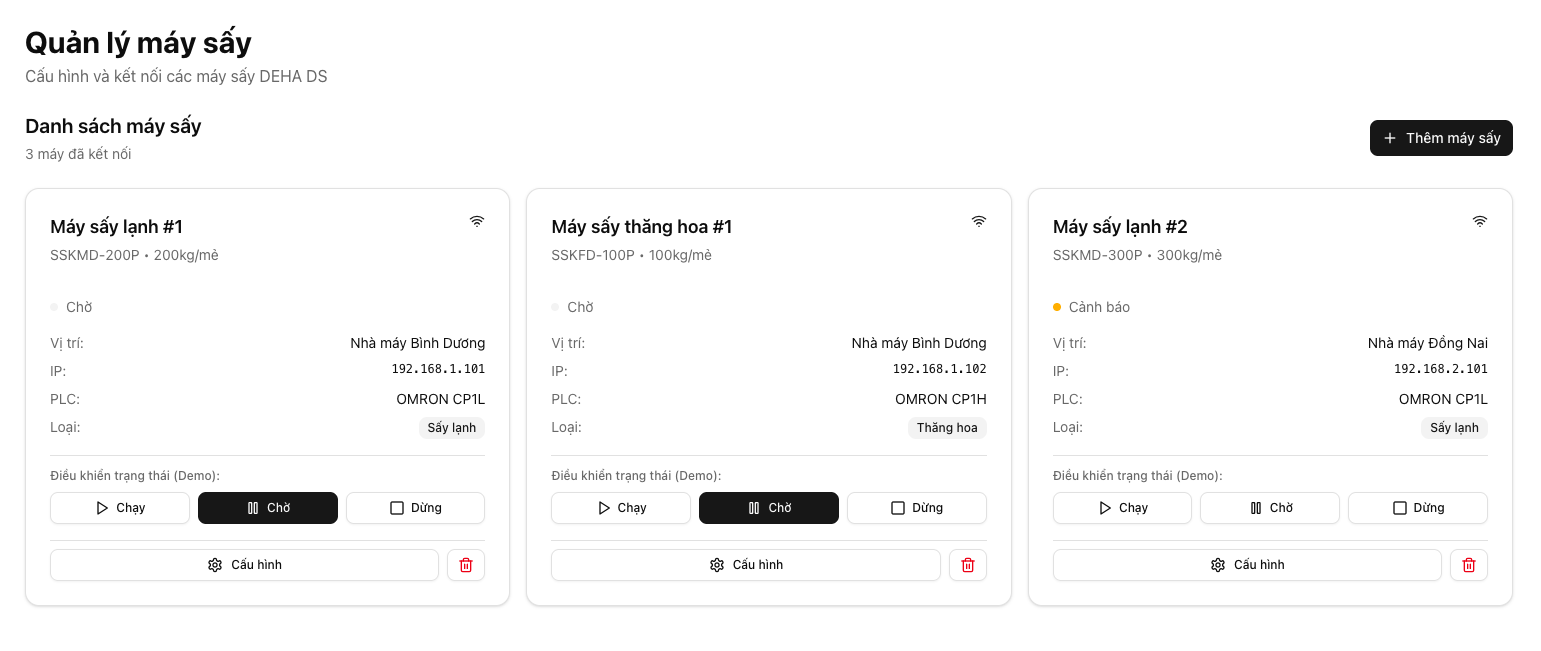

Manage Dryers

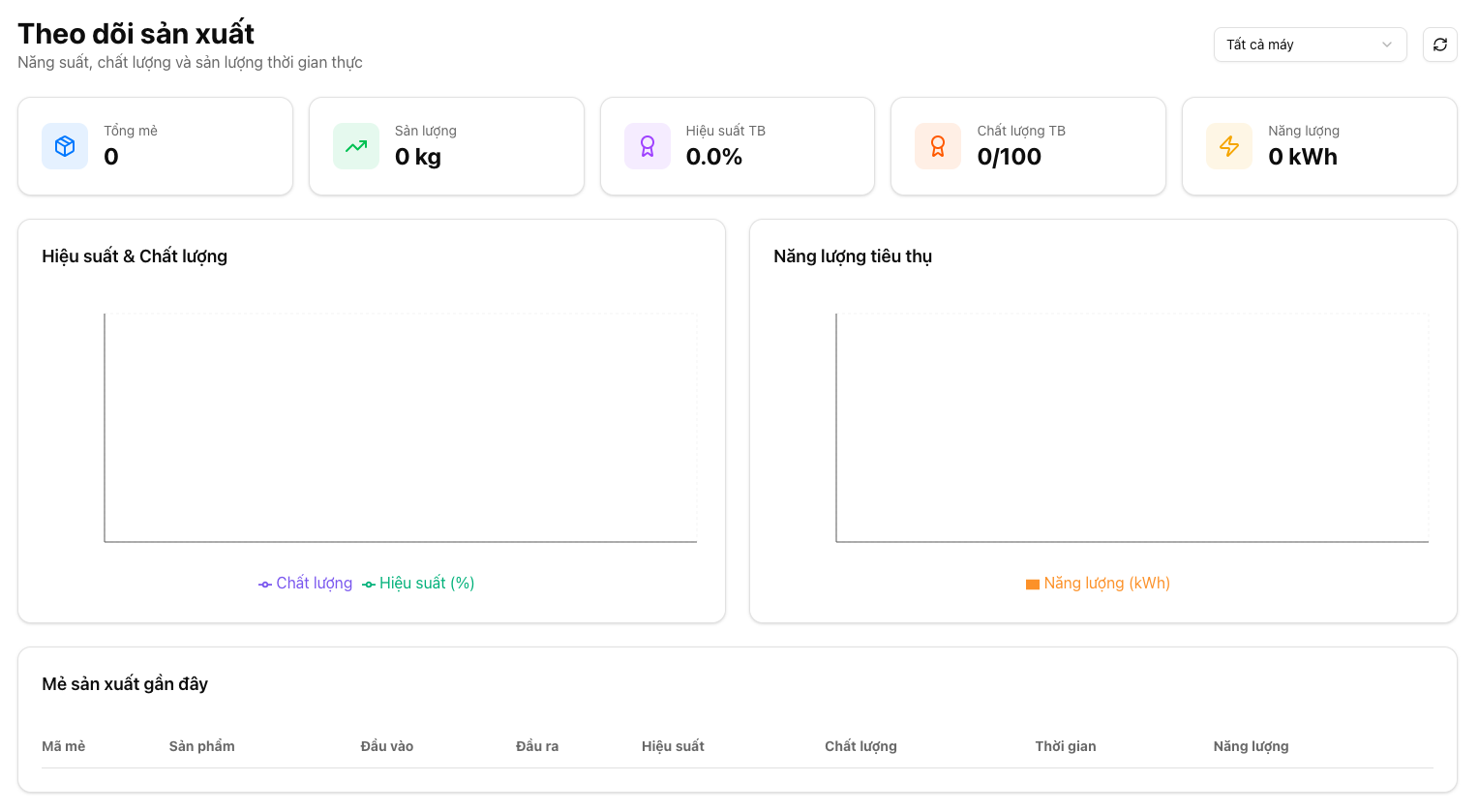

Monitor Productivity

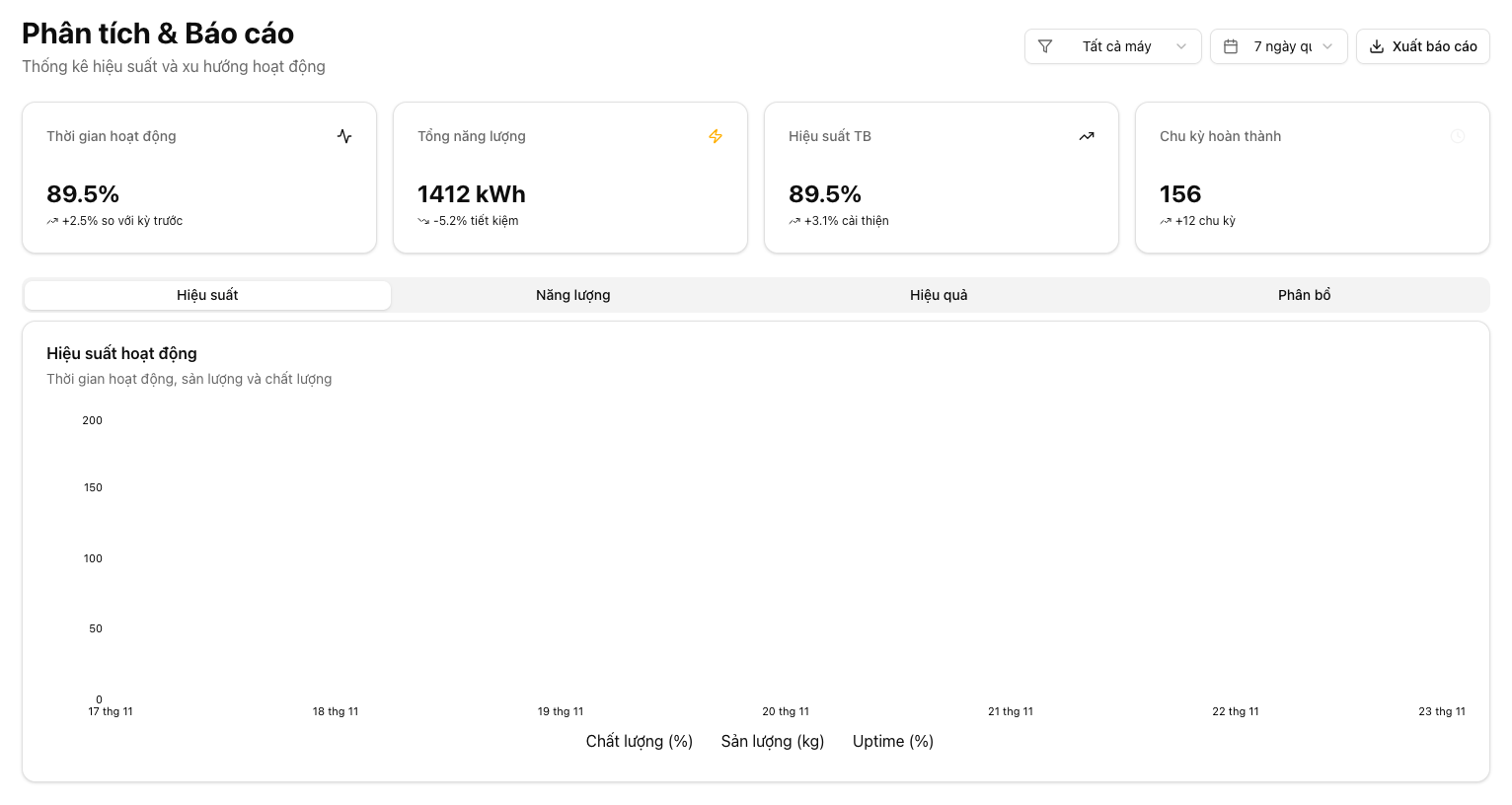

Analyze and Report

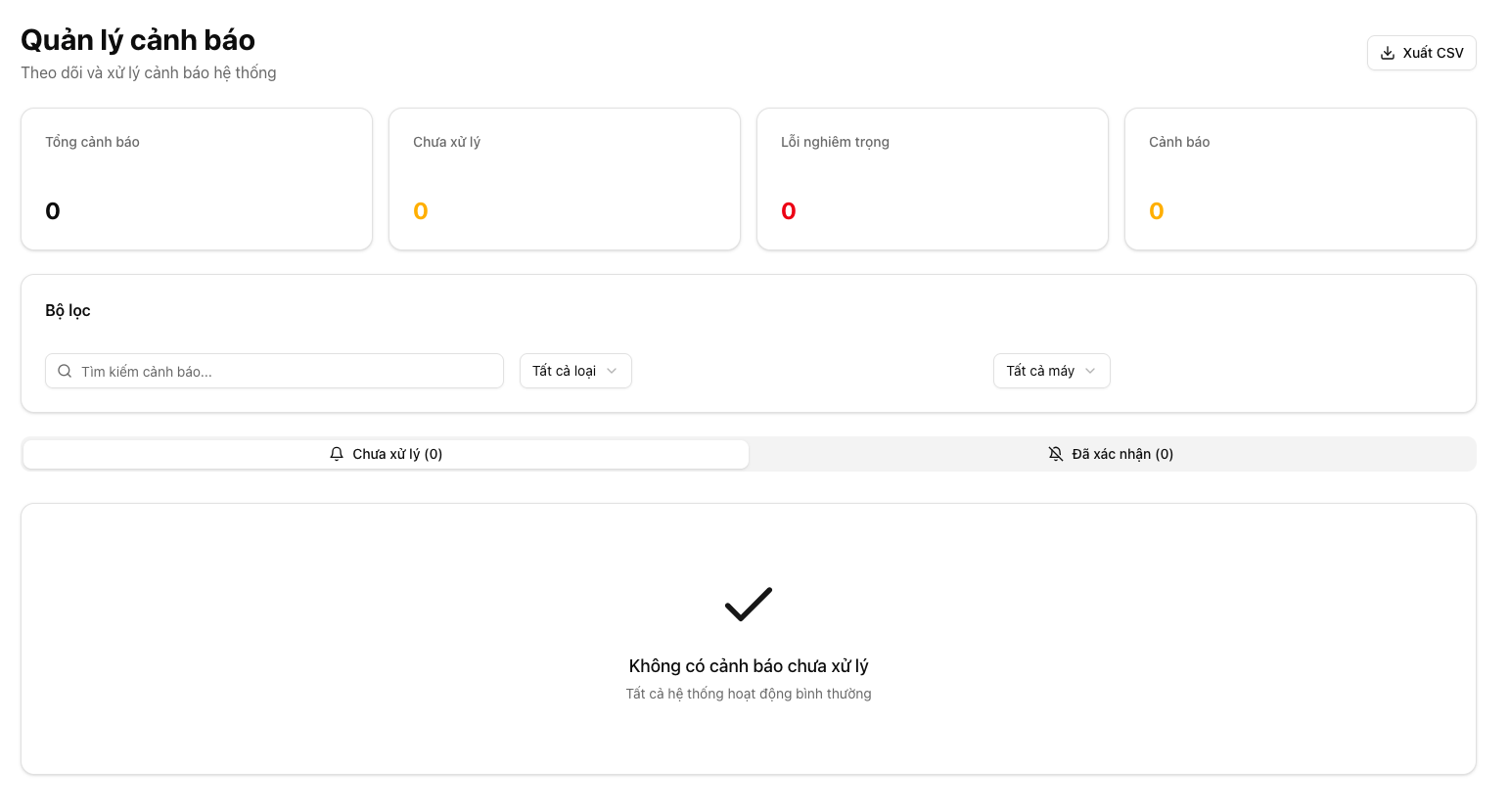

Alert Management

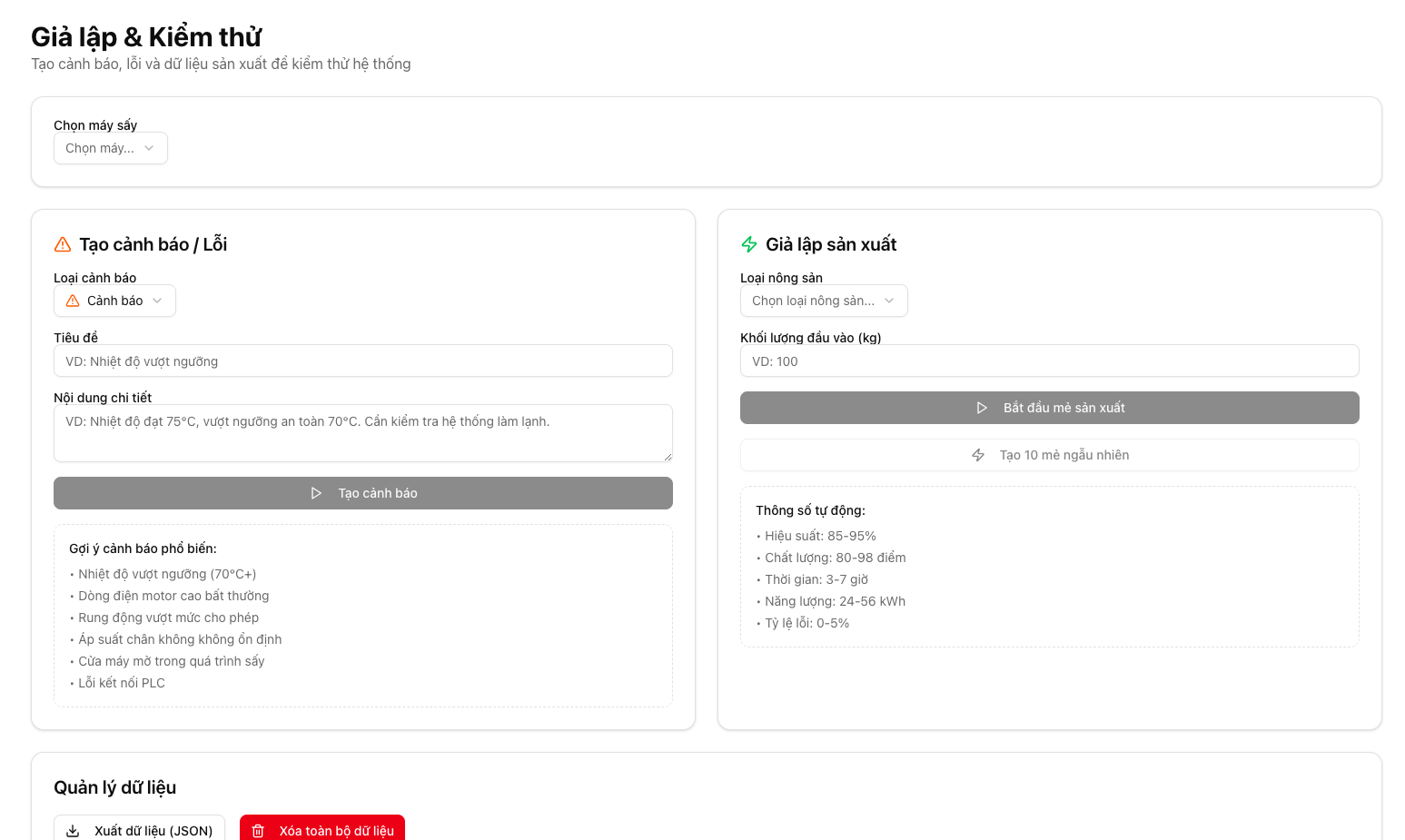

Simulation and Testing