Client Profile

The client is a 100% Korean-invested FDI enterprise specializing in the production of automotive exhaust systems.

Current Situation

Manual production management with poor system integration

Difficulty tracking order progress

Inconsistent quality control

Inaccurate and delayed reporting

Digital Transformation Solution

Fully integrated system with 10 modules

Automation from order placement to warehouse dispatch

User-friendly, intuitive interface

Real-time data and visual reporting

With the comprehensive ERP solution provided by DEHA Digital Solutions, the enterprise benefits from:

25–30% increase in production productivity

15–20% reduction in material waste

Improved product quality

Faster, data-driven decision making

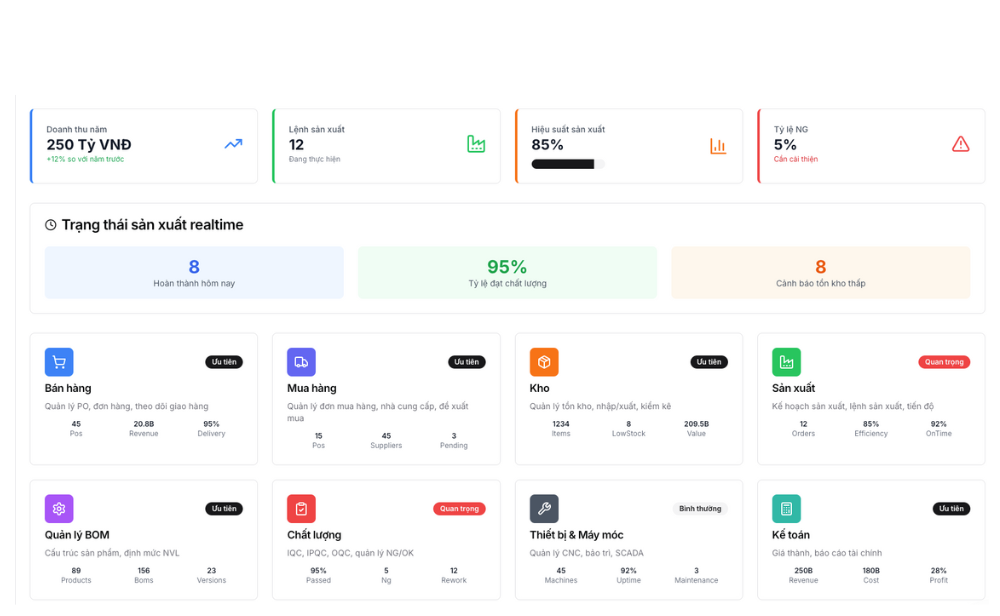

Dashboard Module: Executive Overview

Provides a comprehensive view of manufacturing operations with real-time KPI tracking

Clear charts and graphs showing order status, production efficiency, and inventory levels

Order Management

Create and manage orders with full customer, product, quantity, and deadline information

Track order status in real time

Prioritize orders by urgency

Automatically calculate lead time based on production capacity

Get automated alerts for upcoming deadlines

Direct integration with engineering and production departments

Automatically detect and notify potential issues such as delays, material shortages, or quality concerns

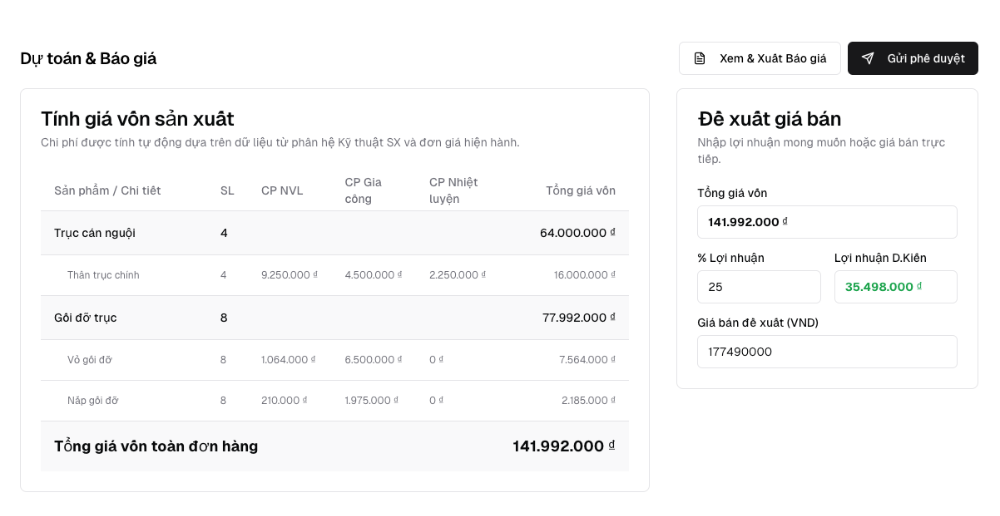

Order Cost Estimation Management

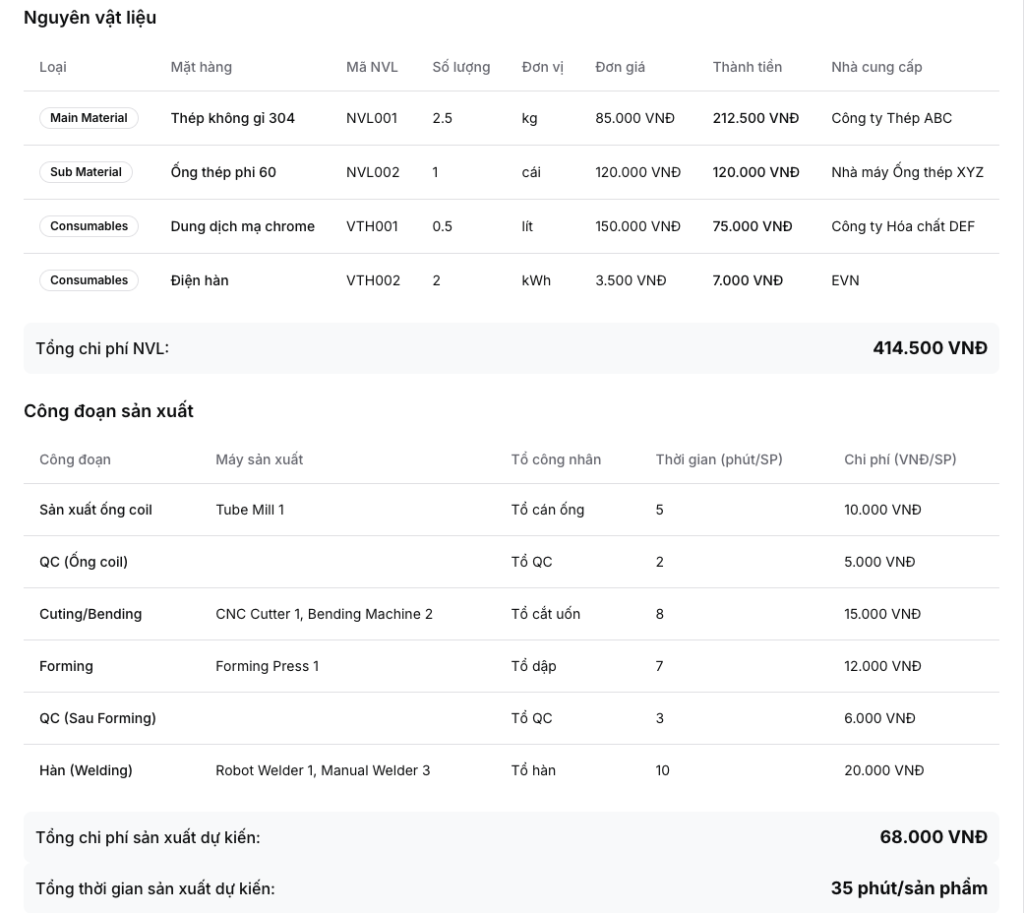

Detailed BOM Design: Create multi-level product structures with full information on raw materials, semi-finished, and finished goods

Version Control: Track and manage BOM versions, easily compare and approve changes

Material Requirement Calculation: Automatically calculate material needs based on BOM and production plan

CAD/CAM Integration: Direct link with design software for technical data import

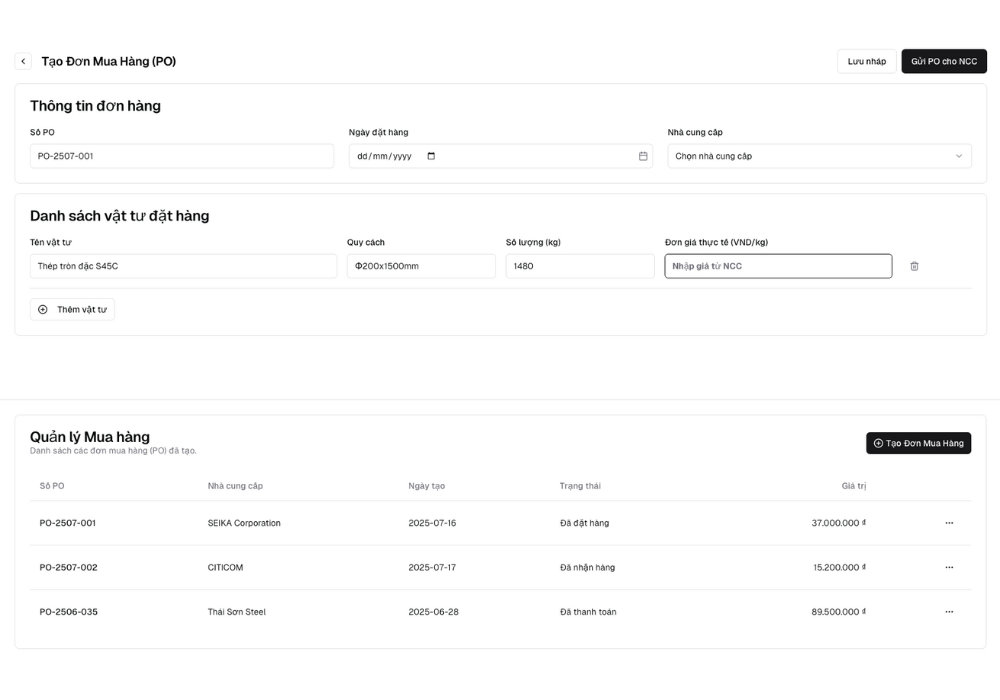

Smart Purchasing

Purchase Requisition Management: Create and approve purchase requests automatically based on production demand and minimum stock levels

Supplier Evaluation: Rate suppliers based on quality, pricing, delivery time, and reliability

Contract Management: Monitor and manage purchasing contracts with alerts for renewal or renegotiation

Production Management

Production Order Creation

Create orders manually or automatically (based on sales orders or MRP)

Assign product, quantity, planned start and end dates

Attach BOM and routing (work process sequence)

Resource Allocation

Assign machines, production lines, and workers

Check production capacity and raw material availability

Progress Tracking

Monitor and update production progress in real time

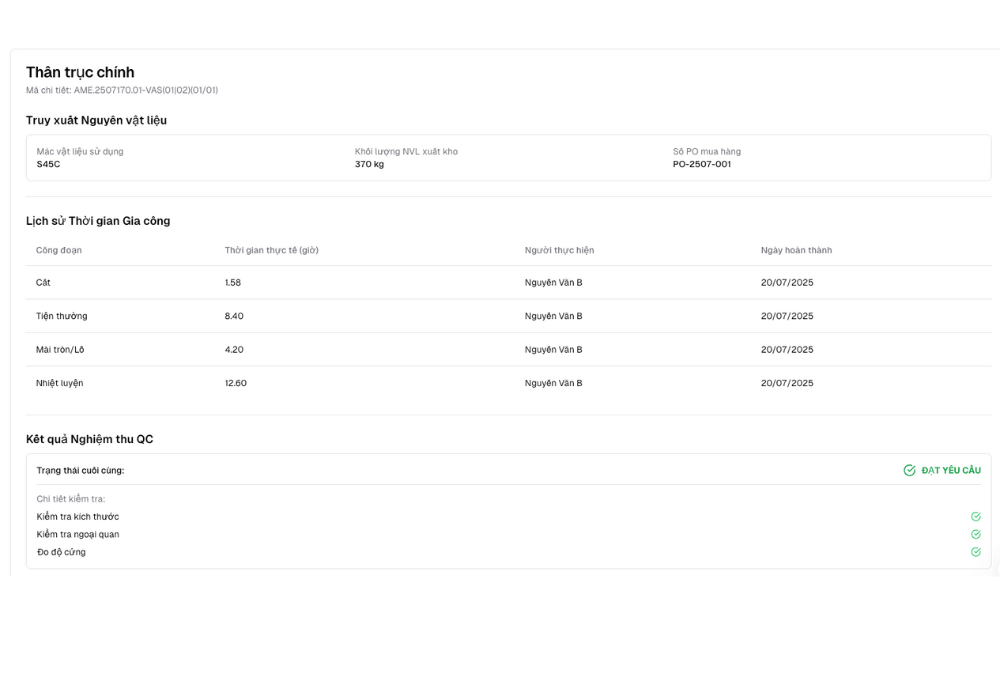

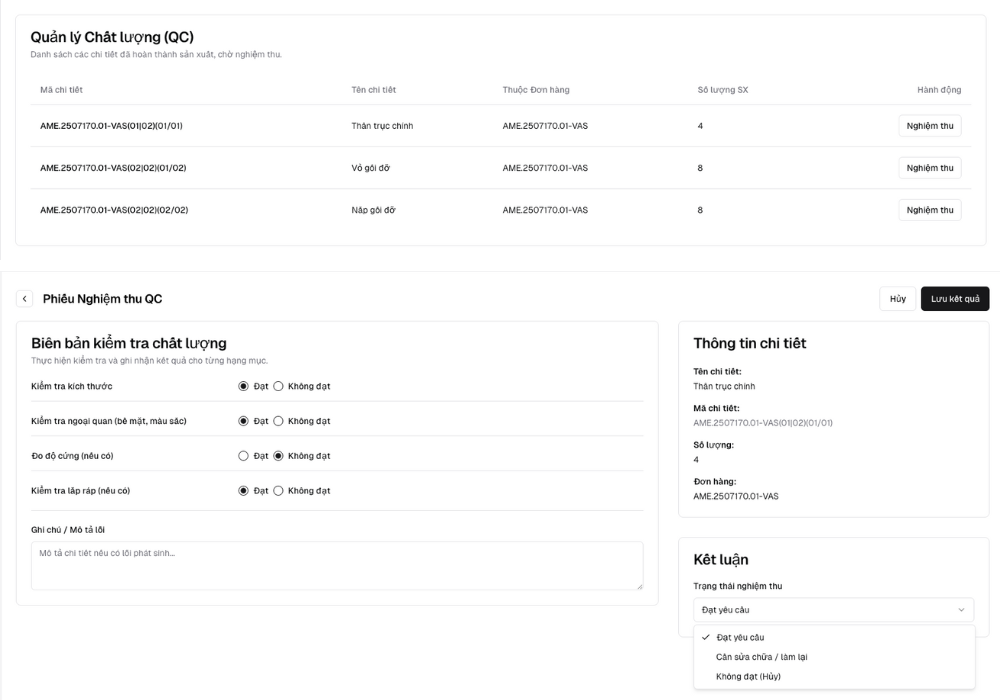

Comprehensive Quality Management

Incoming Inspection: Raw material quality checks with defined criteria and result storage

In-Process Inspection: Quality checks at each production stage with detailed checklists and early defect detection

Final Inspection: Finished product quality verification using standard methods and result recording

Analysis & Improvement: Root cause analysis, trend tracking, and improvement proposals

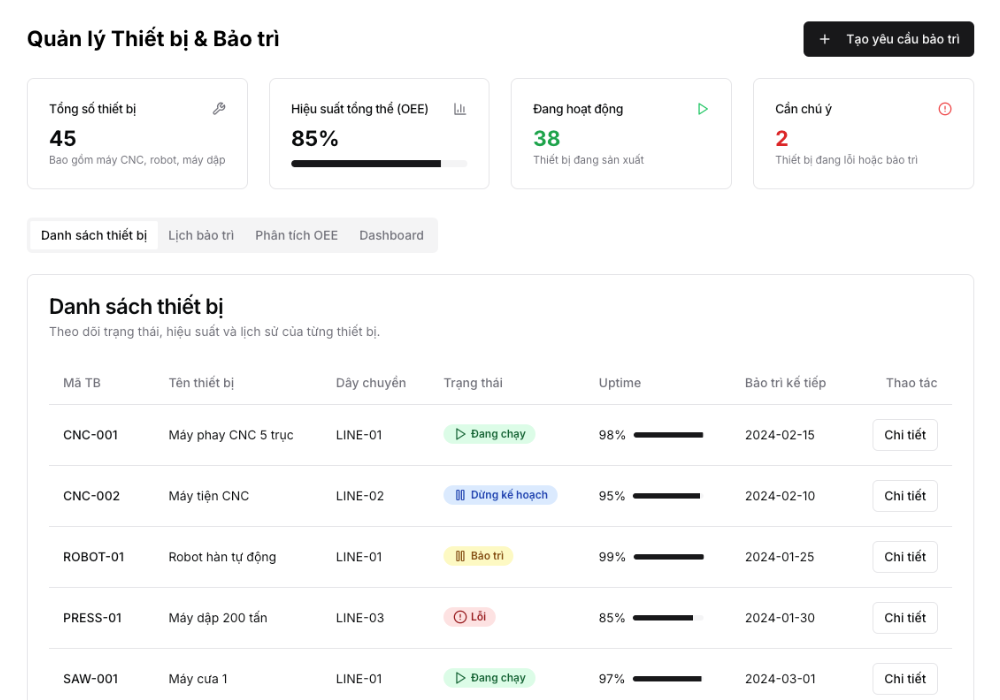

Equipment Performance Management

Monitor OEE (Overall Equipment Effectiveness): Track equipment availability, performance, and quality rates to evaluate overall efficiency

Maintenance Scheduling: Plan preventive maintenance to reduce unexpected downtime and extend equipment lifespan

Downtime Alerts: Receive automatic notifications for machine breakdowns or anomalies

Repair History Management: Log and track maintenance activities, repair history, and spare part usage for each machine

Performance Analysis: Analyze productivity trends and identify bottlenecks for continuous improvement