Client Profile

The client is a precision mechanical processing and equipment manufacturing company based in Ho Chi Minh City.

They supply specialized industrial equipment for major projects such as power plants, steel rolling mills, cement factories, and water treatment facilities.

Current Challenges

Manual production management with poor system integration

Difficulty in tracking order progress

Inconsistent quality control

Inaccurate and untimely reporting

Digital Transformation Solution

Fully integrated system with 9 modules

Automation of processes from order placement to warehouse delivery

User-friendly interface

Real-time data and intuitive reporting

With the comprehensive solution provided by DEHA Digital Solutions, the enterprise gains:

25–30% increase in production productivity

15–20% reduction in raw material waste

Improved product quality

Faster decision-making based on real-time data

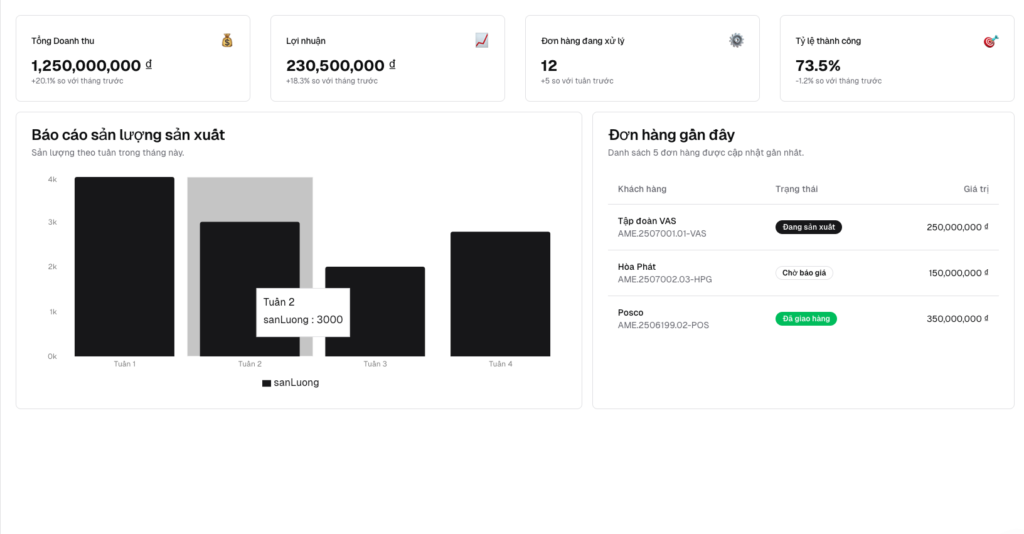

Dashboard Module: Executive Overview

Provides a complete picture of production operations with real-time KPI tracking

Clear charts and graphs display order status, production efficiency, and inventory levels

Automatically detects and alerts for potential issues such as delays, material shortages, or quality non-conformance

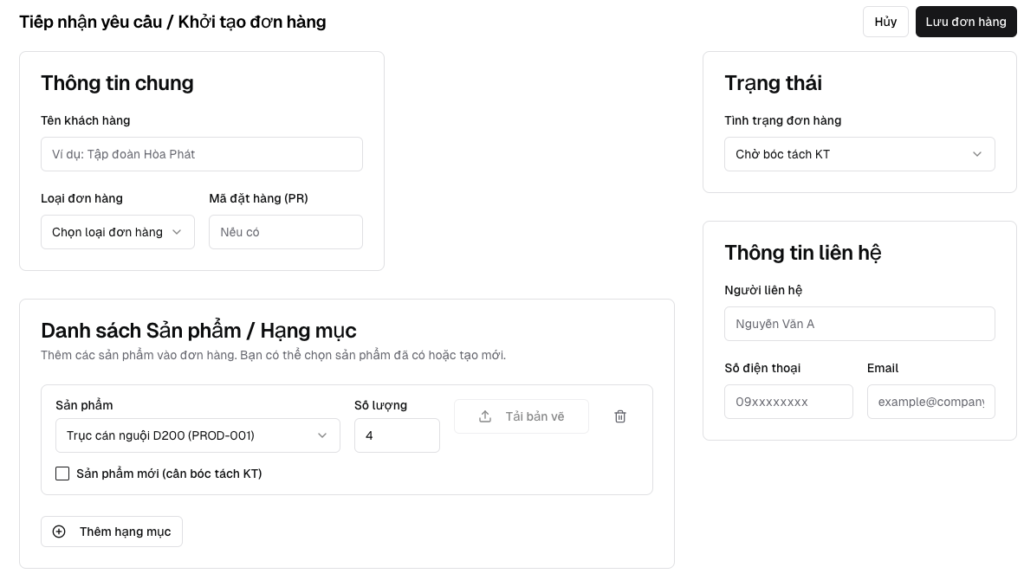

Efficient Order Management

Create and manage orders with full customer, product, quantity, and deadline information

Track order status in real time

Categorize orders by priority level

Automatically calculate expected completion time based on actual production capacity

Receive automatic notifications when orders are nearing deadline

Direct integration with engineering and production departments

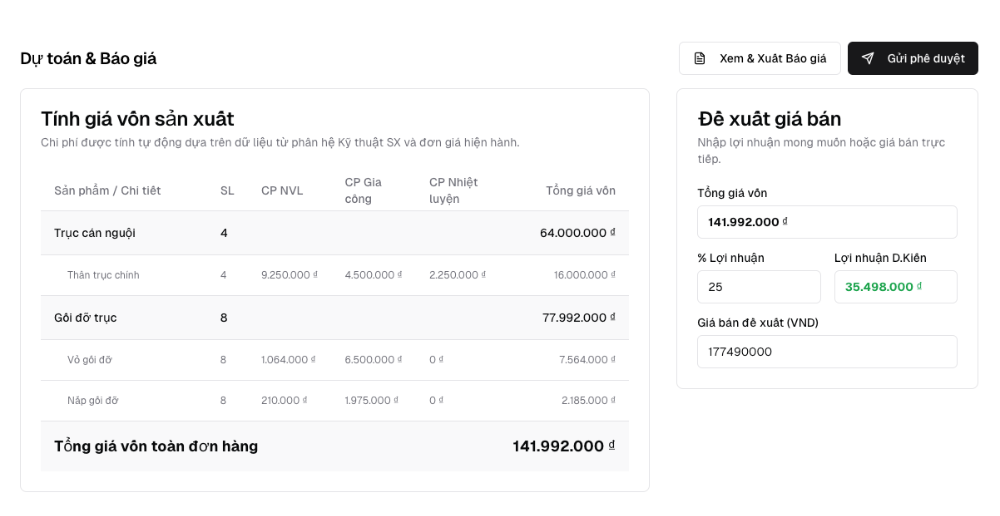

Order Estimation Management

Detailed BOM Design: Create multi-level product structures with full information on materials, semi-finished, and finished goods

Version Control: Track and manage BOM versions, easily compare and approve changes

Material Requirement Calculation: Automatically calculate material needs based on BOM and production plans

Engineering Integration: Directly connect to CAD/CAM software to import technical design data

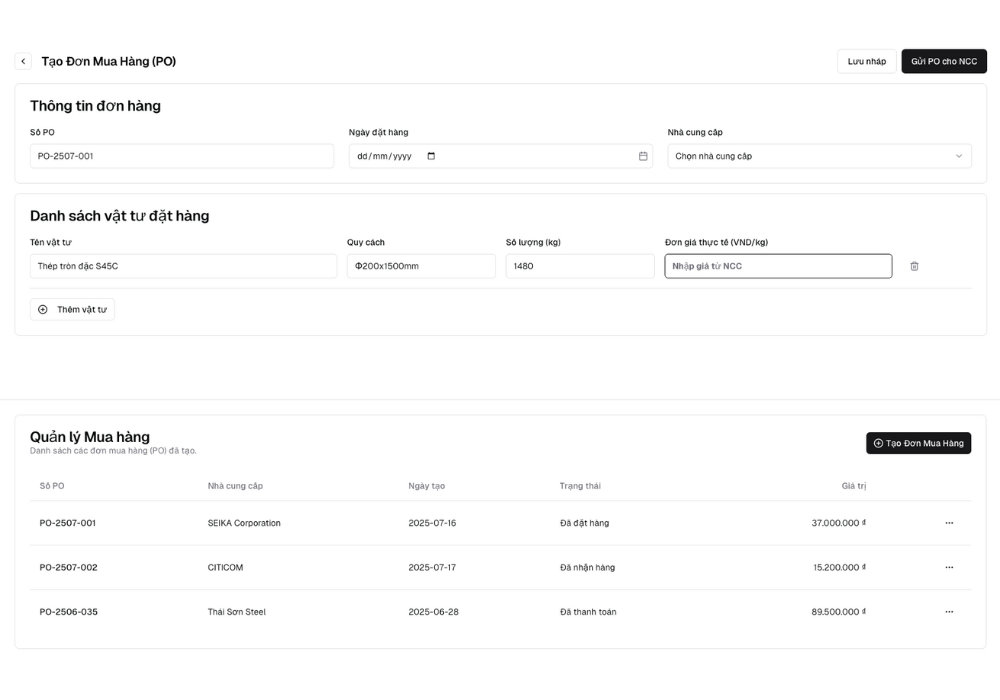

Smart Procurement

Purchase Request Management: Automatically create and approve purchase requests based on production needs and minimum stock thresholds

Supplier Evaluation: Evaluate suppliers based on quality, price, delivery time, and reliability

Contract Management: Track and manage purchasing contracts, with alerts for renewal or renegotiation

Production Management

Production Order Creation

Create orders manually or automatically (based on sales orders or MRP)

Assign product, quantity, and planned start–end dates

Attach BOM (Bill of Materials) and routing (work process steps)

Resource Allocation

Allocate machines, lines, and workers

Check production capacity and raw material availability

Progress Monitoring

Track and update production status in real time

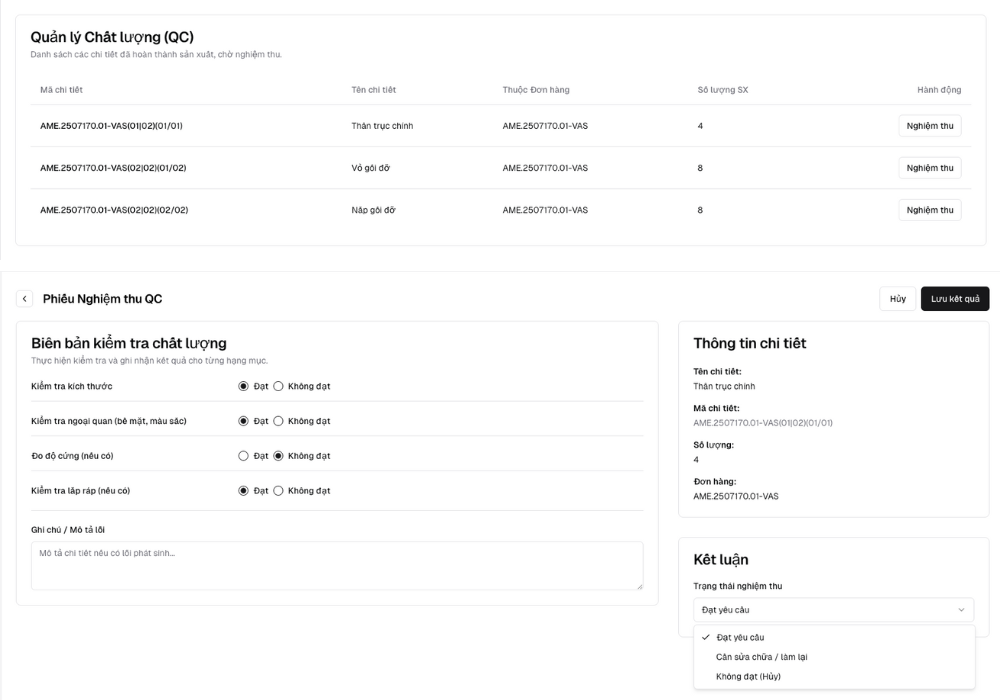

Comprehensive Quality Management

Incoming Quality Control (IQC): Inspect incoming raw materials based on specific criteria and store results

In-Process Quality Control (IPQC): Perform quality checks at each production stage with detailed checklists, enabling early error detection

Outgoing Quality Control (OQC): Verify finished goods using standard inspection methods and record measurement data

Analysis & Continuous Improvement: Analyze root causes of defects, track quality trends, and propose corrective actions