Customer Profile

A company specializing in the production of outdoor sports equipment, specifically paragliders.

Customer Challenges

PRODUCTION

1. Cutting Department

Track production progress.

Manage tasks by order.

Create weekly production schedules based on delivery plans.

2. Paragliding Department

Manage production by serial number.

Create weekly production schedules based on delivery plans.

Automatically calculate and allocate production schedules when delivery priorities change.

3. Backpack Department

Manage tasks by order.

Create weekly production schedules based on delivery plans.

Automatically calculate and allocate production schedules when delivery priorities change.

QUALITY CONTROL & TRACEABILITY

1. Real-time Quality and Output Monitoring

QC scans QR codes and submits real-time quality inspection reports.

Quality control checkpoints include: IQC, Paragliding QC, Backpack QC.

2. Traceability

Trace fabric lot numbers and batches used for any paragliding production order.

Review material inspection history for any lot based on PO number/lot number and material code.

PRODUCTION PLANNING

Configure a standard Working Calendar in the MES: working days, weekends, public holidays.

Enable flexible weekend production policies.

MES must support configurable overtime scheduling on weekends.

Optimized MES planning: detailed progress tracking for each department, updated daily.

MAINTENANCE

Equipment list management.

Preventive maintenance planning.

Unexpected/emergency maintenance handling.

Maintenance request management.

Alerts & notifications.

Overall Solution

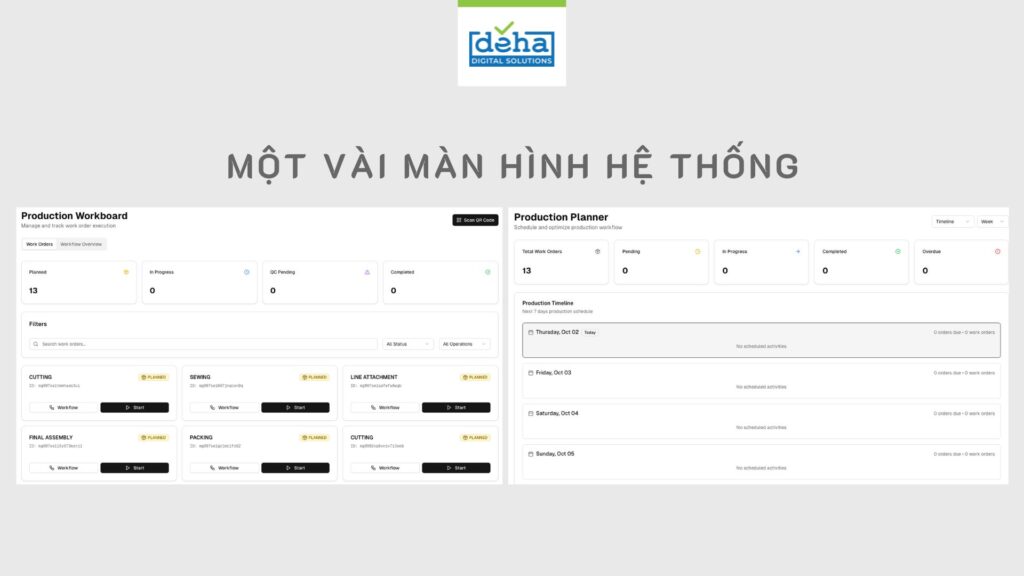

A Selection of Demo System Screens