A Specialized Management Solution for Mechanical Enterprises

- Optimize production costs.

- Enhance competitiveness by helping businesses increase localization capabilities.

Understanding Your Challenges

More than anyone else, we understand the management challenges that mechanical manufacturing businesses in Vietnam must overcome.

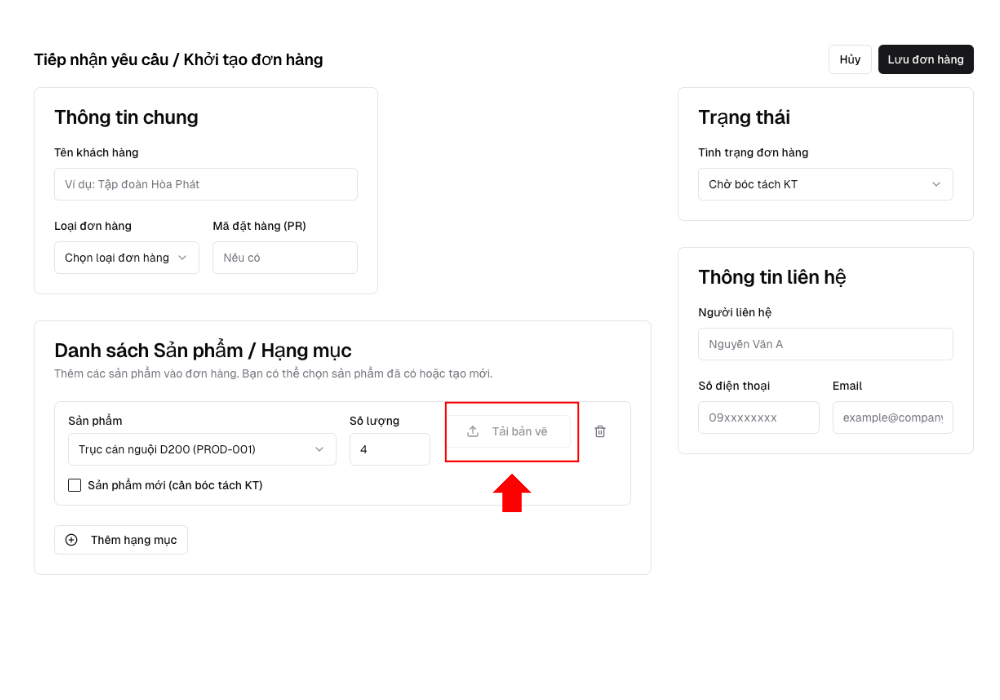

Managing Technical Drawings & Complex BOMs

A mechanical product may be associated with dozens of CAD/CAM drawings, updated frequently.

Without a proper document management system, it often leads to:

Using the wrong drawing during production.

BOM discrepancies between engineering, purchasing, and production.

Difficulties in tracking engineering changes (Engineering Change Management).

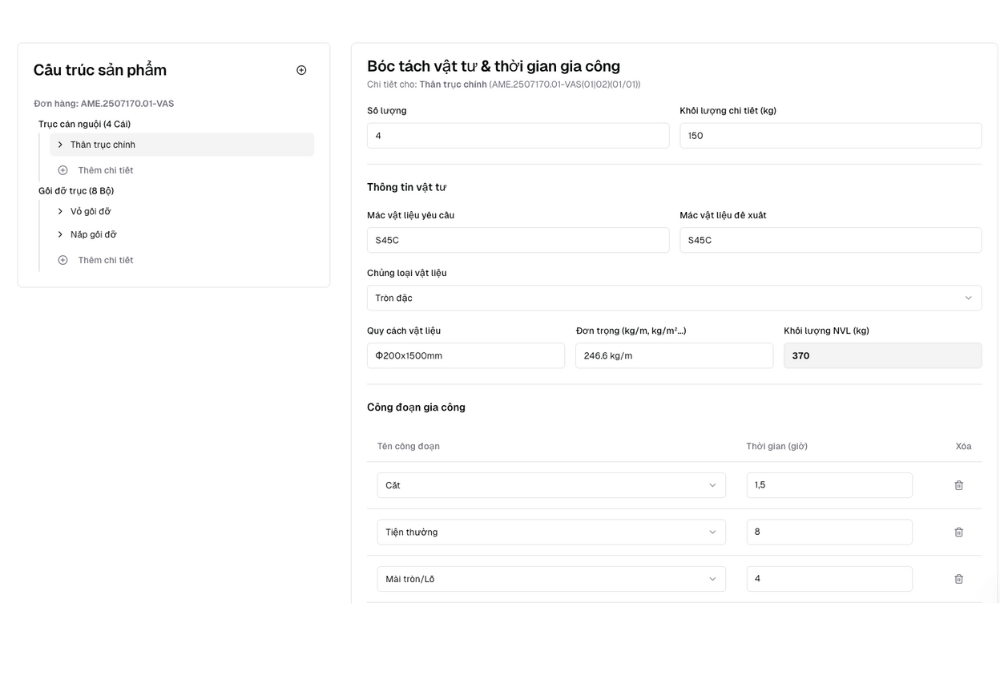

Difficulties in Controlling Material Consumption per Drawing

- A mechanical product consists of many individually fabricated parts made from various materials: sheet metal, shafts, gears, bearings, bolts…

- Poor control of material consumption (BOM) → leads to errors in procurement planning, causing shortages or excess.

- Inventory is hard to manage for materials cut by length, weight, or sheet size (e.g., round steel D25 cut by 1m, steel plates 1.2m x 2.4m…).

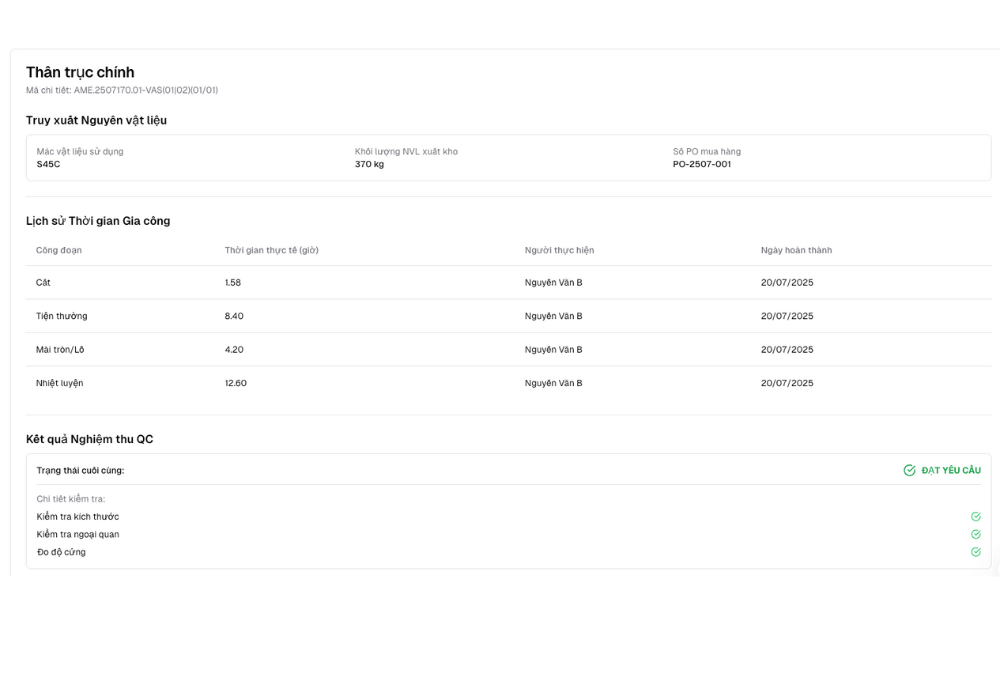

Difficulties in Quality Traceability for Machining Batches

Many mechanical components require inspection of dimensions, surface roughness, hardness, accuracy…

Without a system to record inspection data, it will be difficult to:

Trace product defects back to the process/machine/operator.

Meet ISO 9001 requirements or satisfy demanding customers.

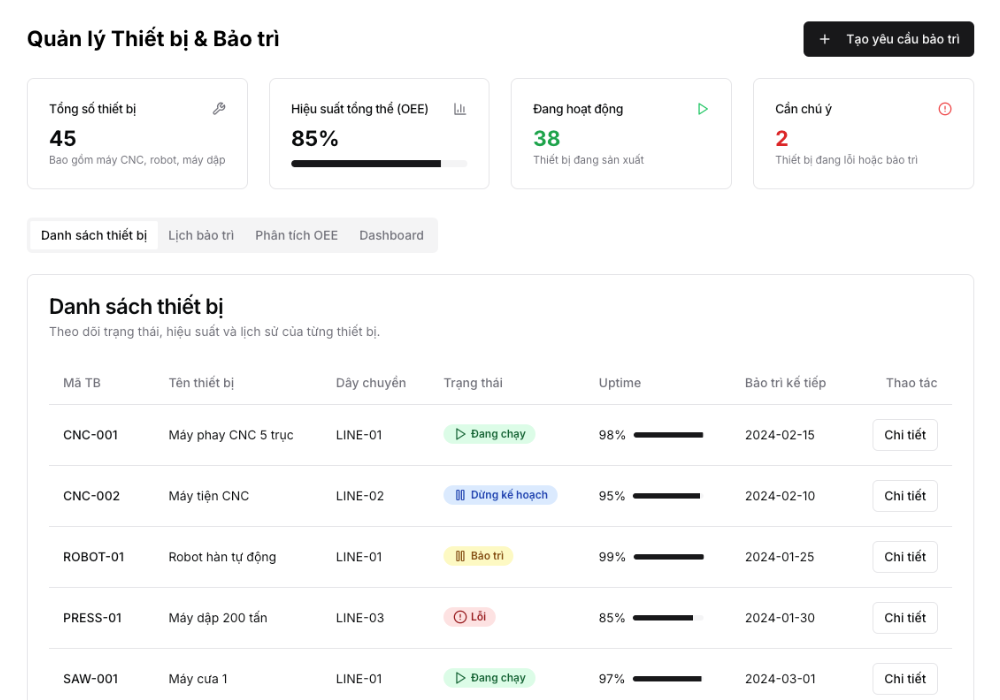

Difficulties in Planning Machine & Labor Capacity

- CNC machines, laser cutters, welding machines… have different setup times depending on the product.

- A lathe can run multiple types of parts – but with varying productivity.

- It is difficult to allocate production orders optimally due to lack of actual data on machine performance, idle time, maintenance schedule…

8 Outstanding Features of ERP for the Mechanical Engineering Industry

An ERP system specifically designed for the mechanical engineering industry will include management features tailored to its unique needs.

This brings superior efficiency that standard ERP systems cannot achieve.

Technical Drawing & Design Change Management

- Store CAD, 3D, and PDF drawings by product code.

- Manage drawing versions and update engineering changes (ECN).

- Synchronize BOMs with each drawing version – minimizing errors in production.

Multi-level BOM Management

- Create multi-level BOMs (by length, weight, area) for assemblies and finished products.

- Support materials in sheet, bar, and tube form, with conversions based on actual dimensions.

- Manage variant BOMs for each order (Engineer to Order).

Tracking Machining Processes (In-house & Outsourced)

- Create production orders based on routing: turning, milling, welding, painting, inspection…

- Track progress of each process via barcode or QR code.

- Manage outsourced machining steps by individual part and supplier.

Machine Management & Optimized Production Scheduling

- Schedule production based on machine capacity and actual setup time.

- Manage machine performance (OEE), maintenance schedules, and downtime alerts.

- Optimize production order allocation to reduce idle time and improve efficiency.

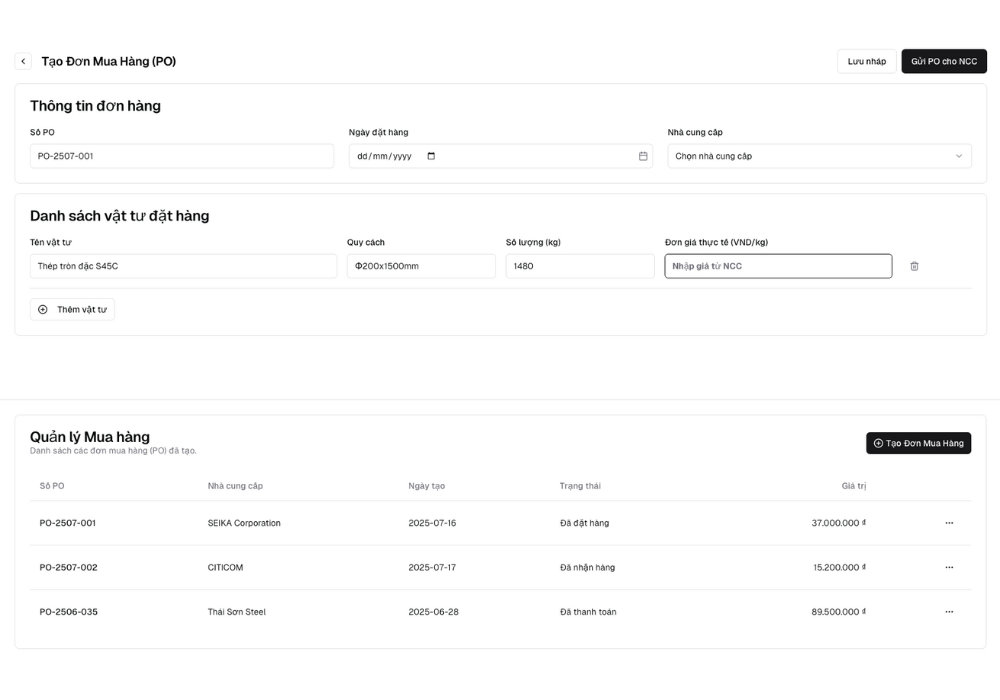

Procurement Management Based on Actual Production Plans

- Automatically suggest purchase orders based on BOM and inventory levels.

- Track delivery times and alert for late materials.

- Evaluate suppliers based on quality, delivery time, and pricing.

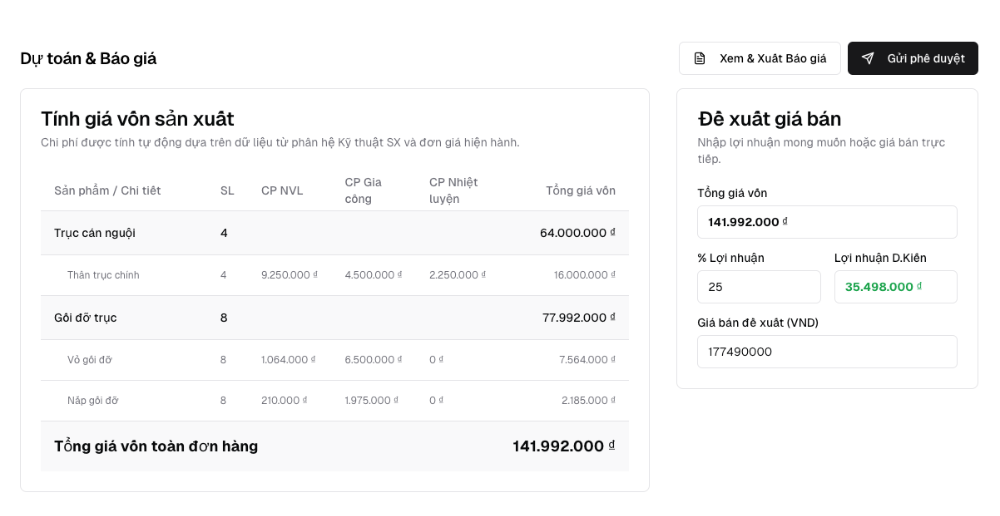

Accurate Product Costing Down to Each Component

- Calculate material, labor, machine, and outsourcing costs for each production order.

- Compare planned costs with actual costs.

- Support precise and transparent costing by order or by individual part.

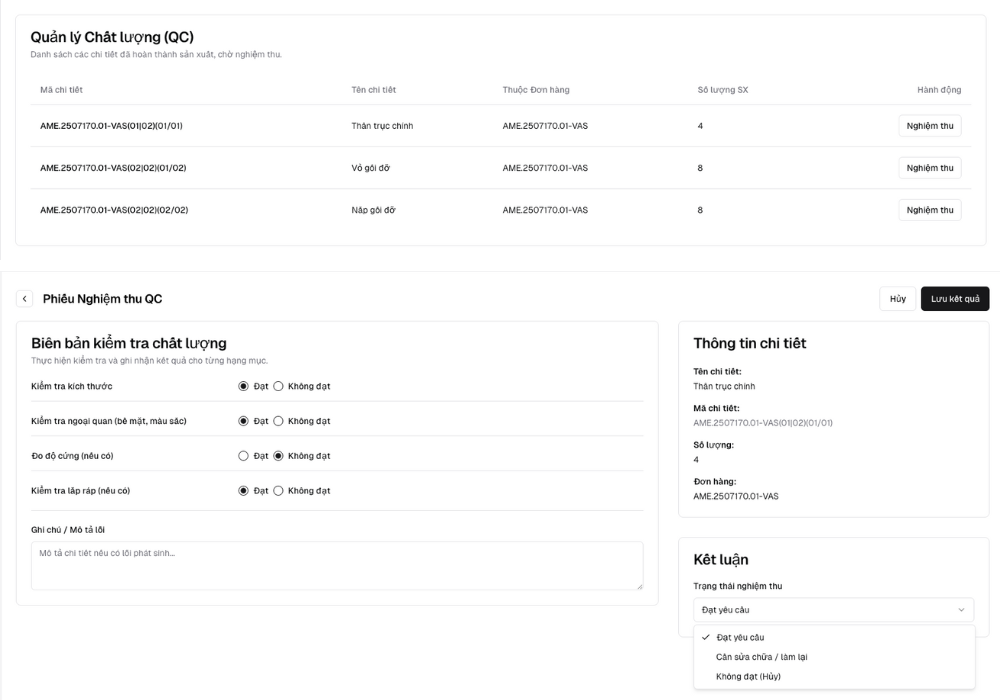

Quality Control & Defect Traceability Management

- Set inspection criteria for each process or product.

- Record inspection results: dimensions, surface roughness, hardness…

- Trace defects by process, personnel, and machine – supporting ISO 9001 compliance.

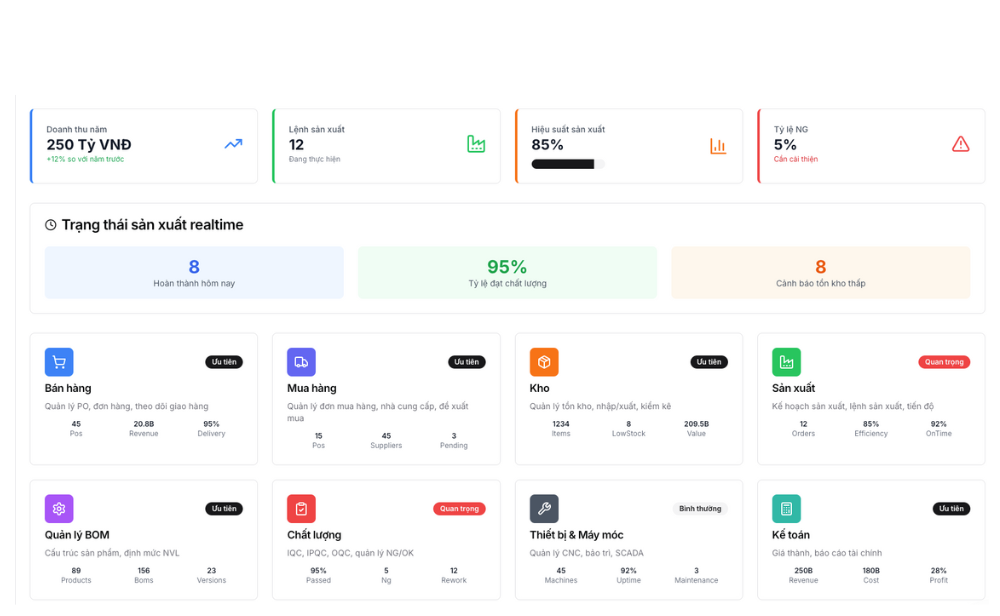

Executive Dashboard & Real-Time Reporting

- Monitor production progress, inventory, machine performance… in real time.

- Automatic alerts for schedule deviations, overconsumption, and other anomalies.

- Enable managers to make fast, accurate decisions – from the office or the shop floor.

Live Demo of ERP System for the Mechanical Engineering Industry

The mechanical ERP system developed by DEHA Digital Solutions offers dedicated versions tailored to the management needs of both machining and assembly production models.

Standardized Processes – Surpassing Productivity

Using the ERP system developed exclusively by DEHA Digital Solutions for the mechanical industry will deliver superior management efficiency.

+30%

Production productivity

+25%

Product quality

-20%

Material Cost

-85%

Waste reduction

Mechanical ERP System: Successful Case Studies

MECHANICAL ASSEMBLY PLANT

A Korean-invested FDI plant specializing in automotive exhaust systems implemented a tailor-made ERP system for mechanical assembly to manage all production activities and enterprise resources.

PRECISION MACHINING PLANT

A precision mechanical machining factory adopted the ERP system to initially manage production and ordering processes paving the way toward comprehensive enterprise-wide management.

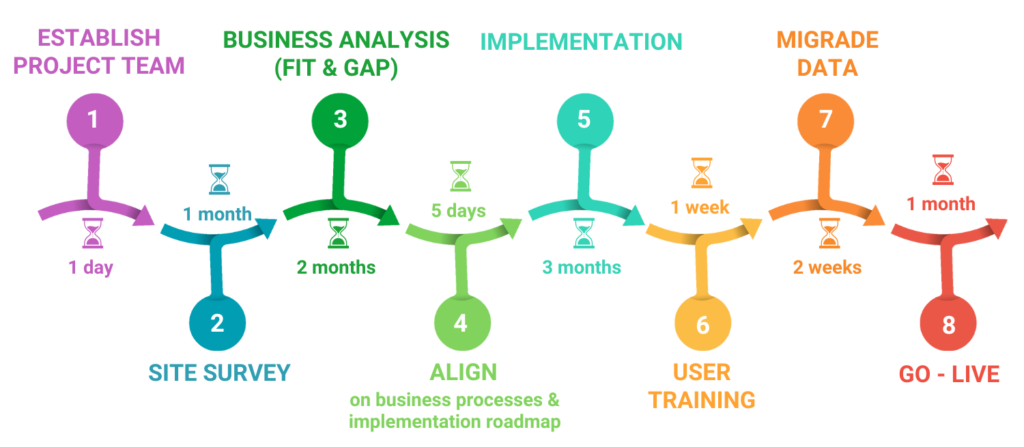

Professional Smart Factory Digital Transformation Roadmap

Start a new project

Briefly describe your project and needs so we can provide quick support.

Experienced Digital Transformation Experts

- Digital Transformation consultant and IFS Cloud implementation specialist in Vietnam with 15 years of experience.

- He has helped Vietnamese and Japanese businesses achieve successful digital transformation, especially in manufacturing sectors such as packaging, electronic devices, and electronic components.

- Expert in implementing IFS ERP Supply Chain Planning (SCP) systems with nearly 10 years of hands-on experience.

- He specializes in consulting and analyzing manufacturing operations, supporting businesses in moving from manual management models to modern systems such as ERP, MES, and WMS.

- Holder of PSM1, PSM2, and DX certifications.

- Specialist in deploying IFS ERP Manufacturing Management Systems with close to 10 years of experience.

- Certified with prestigious IT professional credentials including PSD, PSM1, PSM2, and CMMI. Well-versed in SCADA, MES, ERP, and industrial data communication protocols.

- Skilled in applying AI, Big Data, and Cloud in IIoT environments.